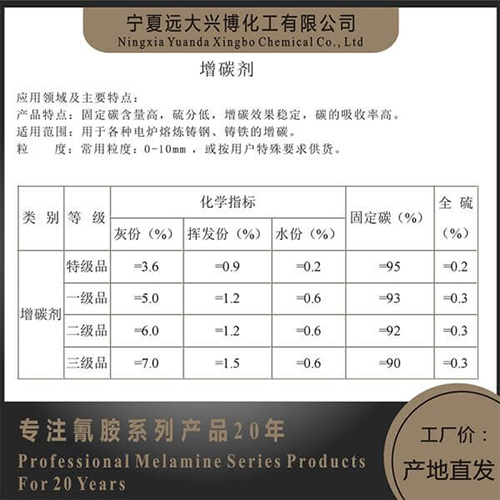

Name | Carburant |

Product Feature | High fixed carbon content, low sulfur content, stable recarburization and high carbon absorptivity |

Application Scope | Used for recarburization of electro-smelting steel casting and iron casting Particle Size: Common Used Particle Size: 0-10mm, or customizable |

Usage | 1) Adjust the carbon content during preparation, add the carburant into lower middle part of an electric furnace together with metal furnace burden according to the requirement of carbon content during steel (iron) liquid melting, do not stir slag while the carburant is melting, otherwise the carburant will be mixed in the waste slag and then carbon absorption is influenced. The carbon absorption rate can reach 90%-95%. 2) Adjust the carbon content after steel (iron) is melted, wherein the carburant can be added on the surface of the steel (iron) liquid and carbon will be dissolved and absorbed through eddy stirring or manual stirring of the steel (iron ) liquid during electro-smelting. The carbon absorption rate can reach 90%-95%. |

Specifications and Items | |

Usage |

| Grade | Fixed Carbon (%) | Total Sulfur (%) | ||||||||||||||||||||||||

Carburetting agent |

|

|

|

| ||||||||||||||||||||||||

Carburetting agent

|

| Extra Grade Products | ≥96 | ≤0.1 | ||||||||||||||||||||||||

(Electric Calcined Material) |

|

|

|

|

Application

Proper use of carbon additives in induction furnace

Aa. Using electric furnaces of more than 5T, the raw material is single and stable, and we recommend the decentralized addition method.According to the requirement of carbon content, according to the proportion of ingredients, the carburizer and the metal burden will be added to the lower part of the electric furnace together with each batch of materials. The carbon absorption rate of one layer of metal burden and one layer of carburizer can reach 90% to 95%.

Bb. The medium frequency induction furnace with about 3T is used. The raw material is single and stable.When first melting or leaving a small amount of iron water in the furnace, the carburizer that needs to be added shall be added to the surface of iron water at one time, and the metal burden shall be added immediately.

Cc. Using small medium frequency electric furnace with raw materials containing high carbon substances such as pig iron, we recommend fine tuning of carbon adding agent.After the steel/iron water is melted, adjust the carbon content, which can be added to the steel/iron water surface. The product can be dissolved and absorbed by eddy stirring of steel (iron) water or manual stirring during smelting in electric furnace. The carbon absorption rate is about 93%.