Product Description

Inoculant

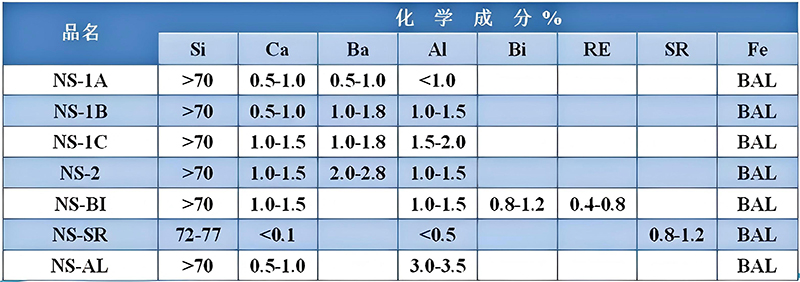

Silicon-Barium inoculant

The silicon-barium inoculant should simultaneously contain an appropriate amount of calcium (wCa = 1.0%~3.0%, wCa = 5.0%~7.0%, etc.) and aluminum (wAl = 1.0%~2.0%). As the barium content increases, the calcium content should also be appropriately increased to enhance the inoculating effect. Furthermore, the coexistence of barium with a certain amount of calcium helps reduce the chilling tendency.

In gray cast iron, silicon-barium inoculant, compared to other inoculants, more readily promotes the formation of uniform and fine Type A graphite. It shows a very low tendency to form Type D and Type E dendritic graphite; even in thin-walled castings with sections of 3-5mm, D+E type graphite does not appear. It significantly increases the eutectic cell count and improves the strength of gray cast iron. The level of barium content greatly influences the strength of gray iron, with medium-barium and high-barium grades being suitable for heavy-section gray iron castings.

In ductile cast iron, it can increase the nodule count, improve the nodularity of graphite, and eliminate cementite. Low-barium inoculants are primarily used in ductile cast iron.

It is used as a deoxidizer in steelmaking and as an inoculant in the foundry industry.

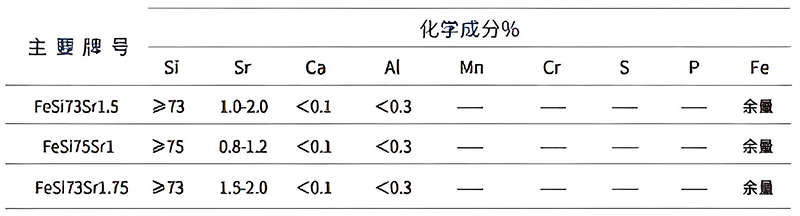

Silicon-Strontium inoculant

Strontium in silicon-strontium inoculant possesses strong inoculation effects. It offers advantages such as reducing chill, decreasing shrinkage porosity, improving cross-section uniformity, and generating minimal dross during treatment.

The typical composition of this inoculant is: Si ≥ 71%, Sr = 0.6%–1.2%, Ca ≤ 0.1%, Al ≤ 0.5%. Higher silicon content typically results in better and more stable inoculation effects. The requirements for calcium and aluminum content are lower but stricter compared to ferrosilicon and silicon-barium inoculants. The primary reason is that elevated levels of calcium and aluminum inhibit the graphitization potential of strontium, rendering the strontium inoculation ineffective.

Silicon-strontium inoculant is primarily used for gray cast iron and ductile iron that does not contain Cerium (Ce). Its prominent feature in gray cast iron is that while reducing chill, it does not significantly increase the eutectic cell count, resulting in a lower tendency for shrinkage cavities and porosity. This helps prevent leakage, making it suitable for castings like cylinder blocks and heads with varying wall thicknesses and strict leak-tightness requirements.