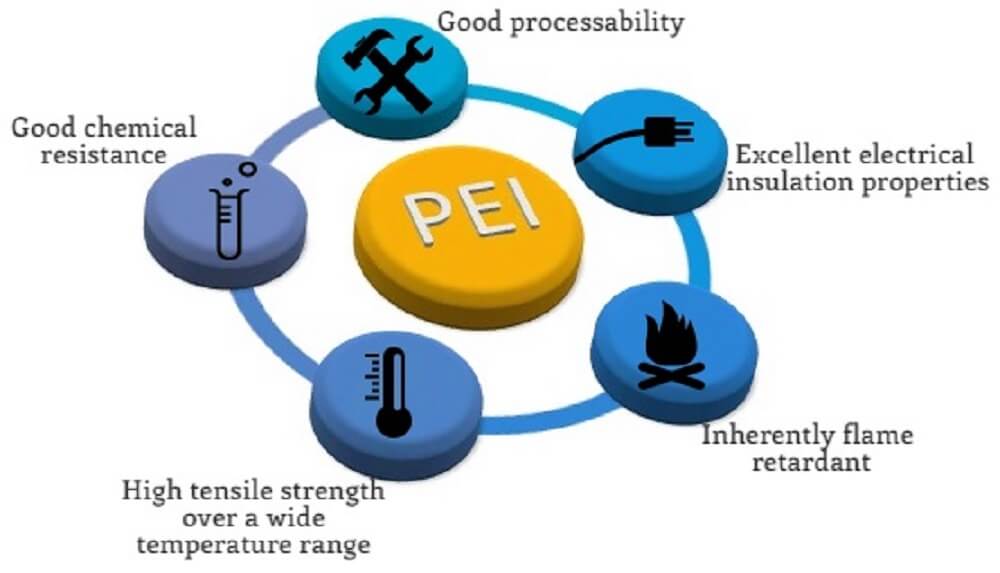

Polyetherimide is characterized by excellent thermal, mechanical and electrical characteristics, and has a place in high-performance applications such as automotive, aerospace, and industrial.

Its characteristics are as follows

High strength to weight ratio

Thermal oxidation stability

Excellent mechanical properties

High temperature resistance

Polyetherimide (PEI for short) is a super engineering plastic made of amorphous polyetherimide. It has the best high temperature resistance and dimensional stability, as well as chemical resistance, flame retardancy, electrical properties, and high strength. , high rigidity, etc., PEI resin can be widely used in high temperature resistant terminals, IC bases, lighting equipment, FPCB (flexible circuit boards), liquid delivery equipment, aircraft internal parts, medical equipment and household appliances, etc.

Main features: 1. High temperature resistance (HDT exceeds 200℃, UL continuous application temperature exceeds 170℃) 2. Excellent flame retardancy (oxygen index greater than 4.7, low smoke volume and UL94V-0/5V) 3. No need to add Flame retardant 4. Outstanding electrical properties (stable dielectric constant and dielectric loss and extremely high dielectric strength in a wide frequency and temperature range) 5. Excellent chemical resistance and radiation resistance 6. Unique strength and rigidity 7. Transparency

Polyetherimide has a wide range of chemical resistance, including resistance to most hydrocarbons, alcohols, and all halogenated solvents; it is also resistant to inorganic acids and short-term resistance to weak bases. For partially halogenated solvents, polyetherimide is a good choice. Its hydrolytic stability is very good, and its tensile strength remains at more than 85% after being soaked in boiling water for 10,000 hours. At 270F, the tensile strength remains at 100% after 2,000 steam hot pressing cycles. Polyetherimide has good resistance to ultraviolet rays and Y-rays. It is processed under 400 megarads of cobalt ray radiation and maintains a tensile strength of 94%.

Polyetherimide's long-term creep resistance under high temperatures and stress allows it to replace metals and other materials in many structural devices. Exhibits good electrical performance under variable temperature, moisture and frequency conditions. The low dissipation factor at GHz frequencies gives polyetherimide high microwave penetrability. It has low levels of ionic contaminants, at 250F100% R. H. And the conductivity after 120 hours of water extraction at 207kPa is above 20 megohms. It can be used as an insulating material for electronic sensor components.