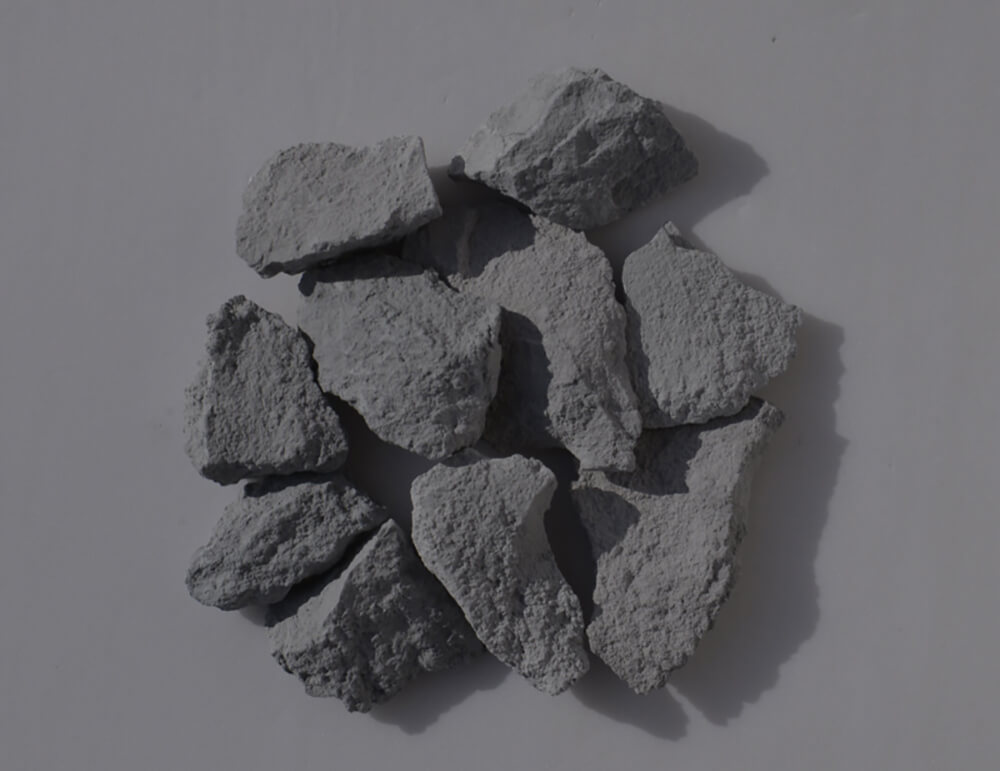

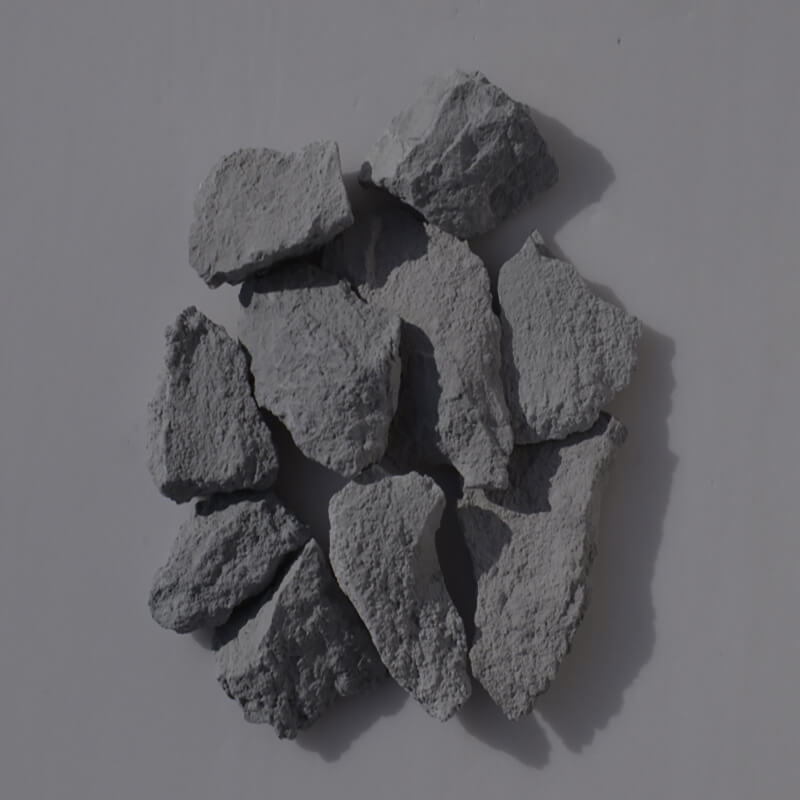

The main components of silicon manganese nitride are accompanied by ferrosilicon nitride and ferromanganese nitride, as well as some other small amounts of mixed elements. The resulting silicon manganese nitride is an off-white product. Silicon manganese nitride is mainly used as a nitrogen-increasing agent for oriented silicon steel, as a nitrogen-increasing agent for high-strength steel, and also as a nitrogen-increasing agent for casting. Domestically, silicon manganese nitride is mainly used to increase the nitrogen content of oriented silicon steel. The invention of using silicon manganese nitride to increase nitrogen in molten steel was invented in 2007. The reason for considering the application at that time was that the manganese nitride was more easily decomposed into molten steel for absorption. That is to say, at the same molten steel temperature, the nitrogen recovery rate of manganese nitride was The single silicon nitride may be higher, and the oriented silicon steel has certain restrictions on manganese. Therefore, it is proposed to use silicon manganese nitride to achieve the double effect of improving nitrogen recovery without increasing too much manganese. Using silicon manganese nitride as orientation silicon steel to increase nitrogen compared with ferro silicon nitride with similar nitrogen content, the recovery rate of nitrogen is high, and the fluctuation range of molten steel is small. After nearly four years of use, all silicon nitride manganese for smelting oriented silicon steel Increase nitrogen.