Coal columnar activated carbon used for the purification of toxic gas, waste gas treatment, industrial and domestic water purification, solvent recovery and other aspects. Moreover, it is widely used in various aspects of industrial and agricultural production, such as non-alkali deodorization (refined mercaptan), ethylene desalination water (refined filler), catalyst support (palladium, platinum, rhodium, etc.), water purification and sewage treatment in the petrochemical industry. Treatment and protection of water quality in power plants; Chemical industry of chemical catalysts and carriers, gas purification, solvent recovery and oil decolorization, refining; Food industry beverage, alcohol, MSG mother liquor and food refining, decolorization; Gold extraction and tail liquid recovery in the gold industry; Environmental protection industry sewage treatment, waste gas and harmful gas treatment, gas purification; And related industries of cigarette filter, wood floor moistureproof, smell absorption, automobile gasoline evaporation pollution control, various macerate liquid preparation.

Name | Columnar activated carbon from coal | |||

HS code |

| |||

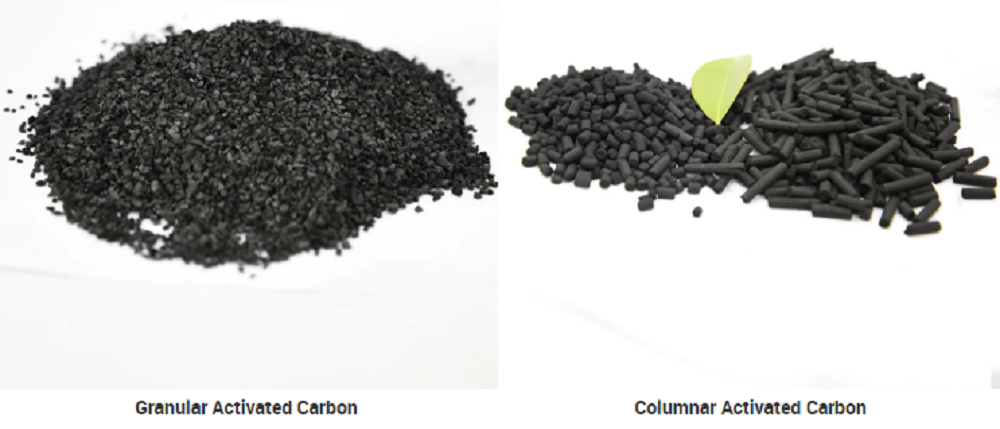

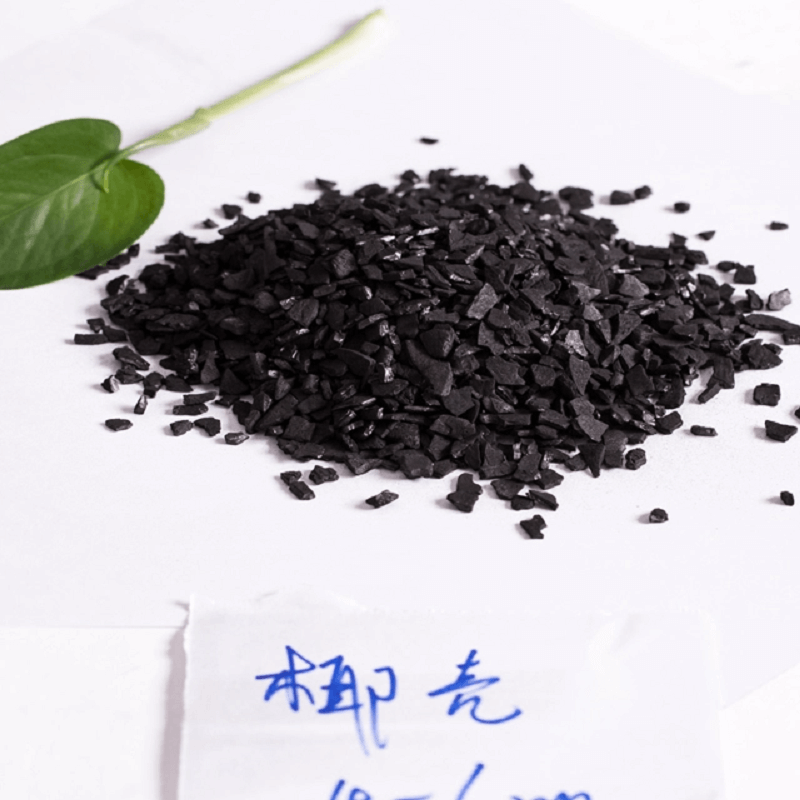

Product Brief | Coal-based columnar activated carbon is made of high-quality anthracite as raw material, refined and processed by advanced technology, and the appearance is black cylindrical particles; it has reasonable pore structure, good adsorption performance, high mechanical strength, easy repeated regeneration, low cost, etc.; For purification of toxic gases, waste gas treatment, purification treatment of industrial and domestic water, solvent recovery, etc. | |||

use | Coal-based columnar activated carbon is used in the purification of toxic gases, waste gas treatment, purification treatment of industrial and domestic water, and solvent recovery. And it is widely used in various aspects of industrial and agricultural production, such as alkali-free deodorization (refined dethiol), ethylene demineralized water (refined filler), catalyst carrier (palladium, platinum, rhodium, etc.), water purification and sewage treatment in the petrochemical industry; electricity Water treatment and protection of power plants in the industry; decolorization and refining of chemical catalysts and carriers, gas purification, solvent recovery and oils and fats in the chemical industry; refining and decolorization of beverages, alcohol, monosodium glutamate mother liquor and food in the food industry; gold in the gold industry Extraction, tail liquid recovery; sewage treatment, waste gas and harmful gas treatment, gas purification in the environmental protection industry; and cigarette filters, wood floor moisture resistance, taste absorption, automobile gasoline evaporation pollution control in related industries, and preparation of various impregnant solutions Wait. | |||

Various indicators | ||||

Analysis Project | Test Data | Analysis Project | Test Data | |

Iodine value | ≥850mg/g | Mechanical strength | ≥90% | |

Specific surface area | 500-900m/g | Water points | ≤10% | |

Packing density | 0.45-0.55g/cm | PH value | Produce on request | |

Benzene adsorption | ≥400mg/g | Methylene blue value | ≥8ml/g | |

Pack | Polypropylene woven bag plus inner film 500 kg packaging; can also be packed according to customer requirements. | |||