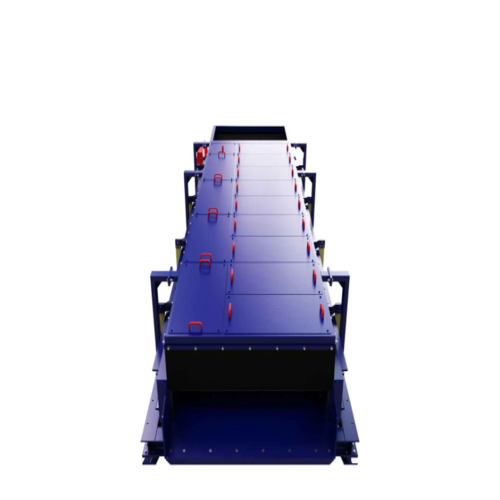

Screening crusher CR600, crusher

Sandvik screening crusher

Sandvik's screening crusher combines innovative design with advanced technology. The compact design of the machine has extremely high material handling capacity, which greatly facilitates the overall layout design of the crushing and processing workshop, and can significantly reduce the size and floor space of the workshop, thereby reducing investment costs.

Feed material

Sandvik CR610 and CR620 screening crushers are widely used for primary, secondary and tertiary crushing of lignite, coking coal and other similar low to medium hardness raw materials.

Working method

In the primary crushing stage, the material passes through the counter-rotating crushing rollers of the CR610 screening crusher to initially reduce the size of the feed.

The crushing bars attached to the bottom can also assist in the crushing process.

The CR620 type screening crusher with two-side feed is used in the second and third stages of crushing. The material passes between the outward rotating crushing rollers and the toothed wear plates on both sides. The shear and tension forces generated by the low speed and high torque of the crushing rollers will further process the material size. When choosing a suitable type of screening crusher, the criteria mainly depend on the technical parameters required, such as material properties, feed material size, desired discharge size and output, while investment and operating cost factors must also be considered.

Parameter Specifications

Feed material size: up to 2000 mm (79 in)

Discharge size: minimum less than 40 mm (2 in)

Processing capacity: up to 6000 mtph (6614 stph)

Crushing ratio: 1:3~1:10

Installed power: 2 x 800 kW (1073 hp)