Sputtering target material process flow:

Raw material powder → powder smelting → powder mixing → press molding → atmospheric sintering → plastic processing → heat treatment → ultrasonic flaw detection → water cutting → machining → metallization → binding → ultrasonic testing → ultrasonic cleaning → final inspection → packaging out of the warehouse

Ingredient Quality Control

Raw material composition analysis:

Through ICP, GDMS and other equipment testing and analysis, metal impurity content, to ensure that the purity of the standard;

Through the carbon and sulfur analyzer, nitrogen and oxygen analyzer and other equipment to detect non-metallic impurity content.

Metallographic flaw analysis:

Detect the output target material through flaw detection equipment to ensure that there are no defects and shrinkage holes inside the product;

Detecting the degree of internal grain of target material through metallographic test to ensure fine grain.

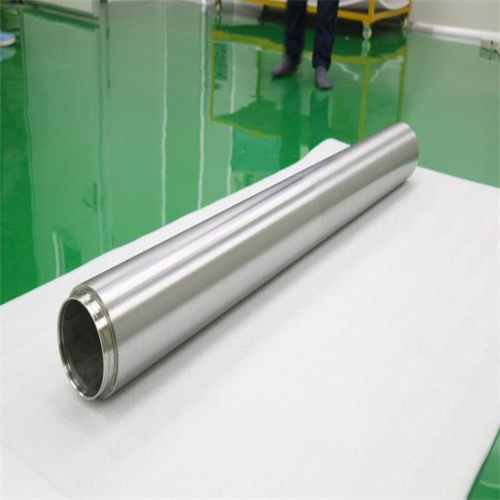

Appearance size testing:

Through micrometer and precision caliper, measure the product size to ensure that it meets the requirements of customer drawings;

Measuring the surface finish and cleanliness of products through surface cleanliness measuring instrument.