Brand: Sincere

Model: Vacuum furnace

Place of Origin: Ningxia, China

Whether to export: yes

Custom processing: Yes

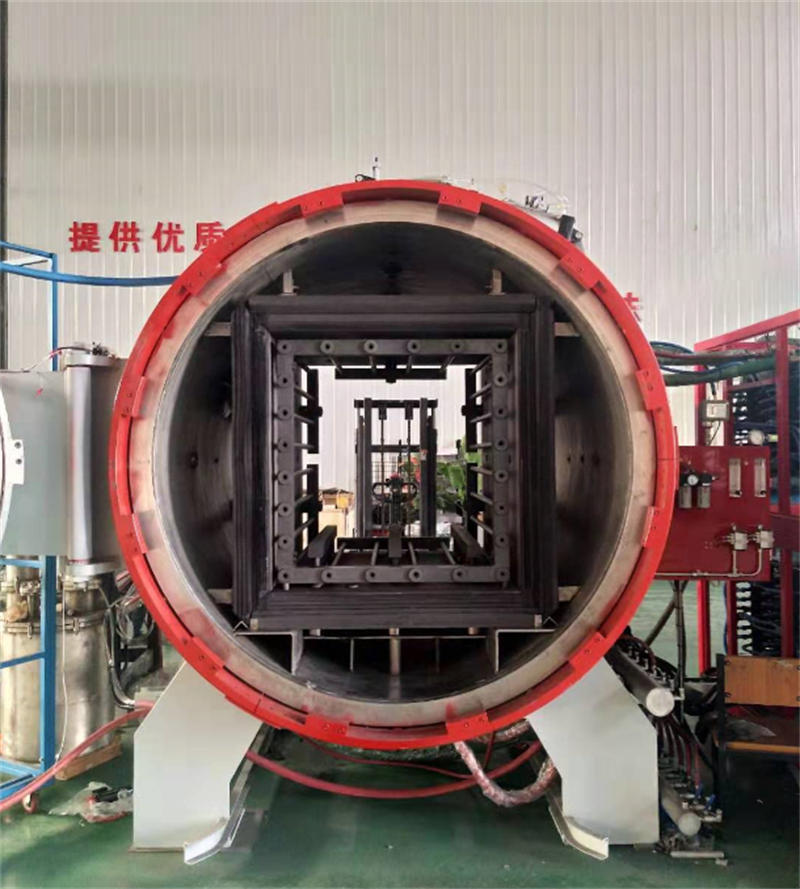

WW202020 high-temperature ultra-high vacuum sintering furnace: WW202020 is a high-temperature ceramic sintering equipment integrating high temperature and ultra-high vacuum. It adopts double PFEIFER molecular pump system and six-sided independent temperature control tungsten mesh heating system. The equipment has the characteristics of beautiful and compact appearance, ultra-high vacuum, clean temperature uniformity area, and excellent temperature uniformity.

Performance characteristics: uniform temperature zone: 500*500*500mm, the main feature is ultra-high vacuum, the vacuum degree can reach 6.7×10-8 Torr; the thermal field uniformity performance is excellent, the temperature uniformity can reach ±1℃, and the leakage rate can reach 0.001 pa/h, the temperature can be up to 2000℃, and the user can set to realize vacuum sintering and atmosphere sintering.

Application field: Used for sintering of high temperature ceramic materials or material sintering/heat treatment under high temperature and ultra-high vacuum conditions

Details Images

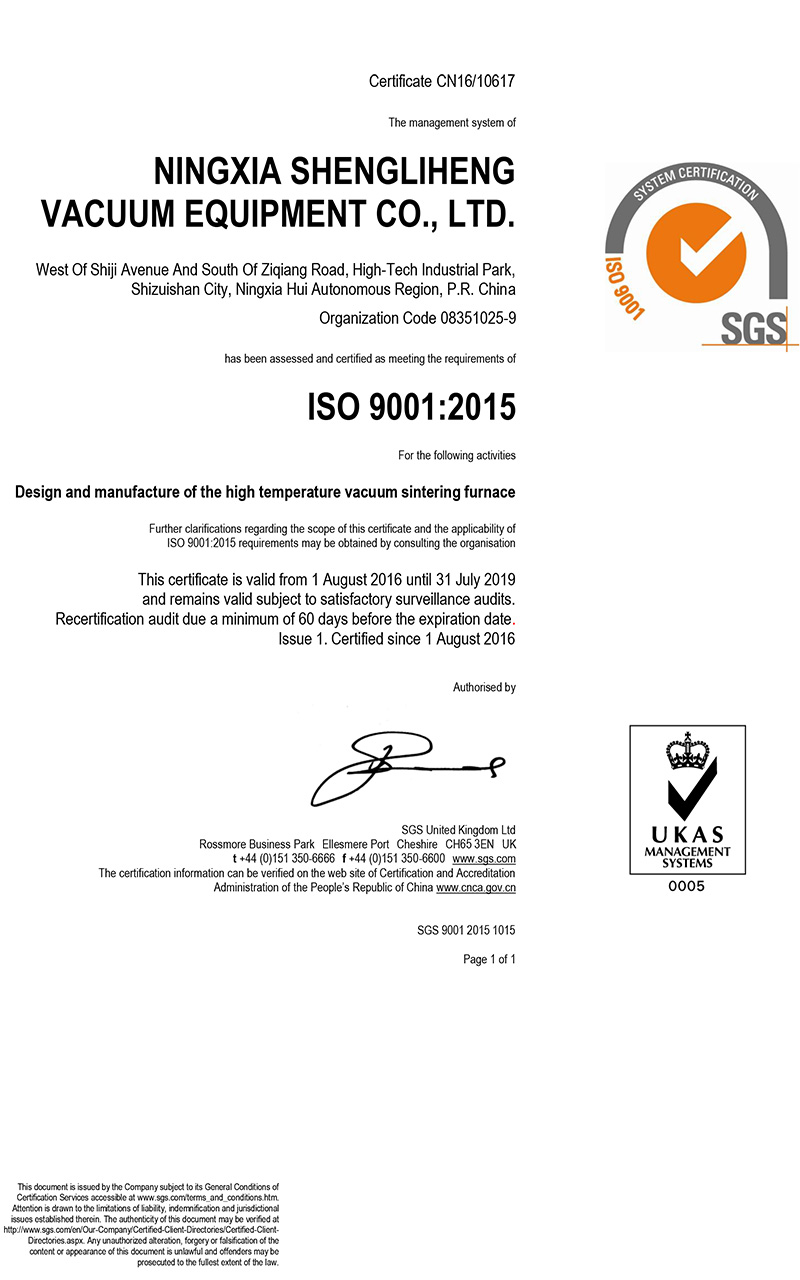

Certifications

Packing & Delivery

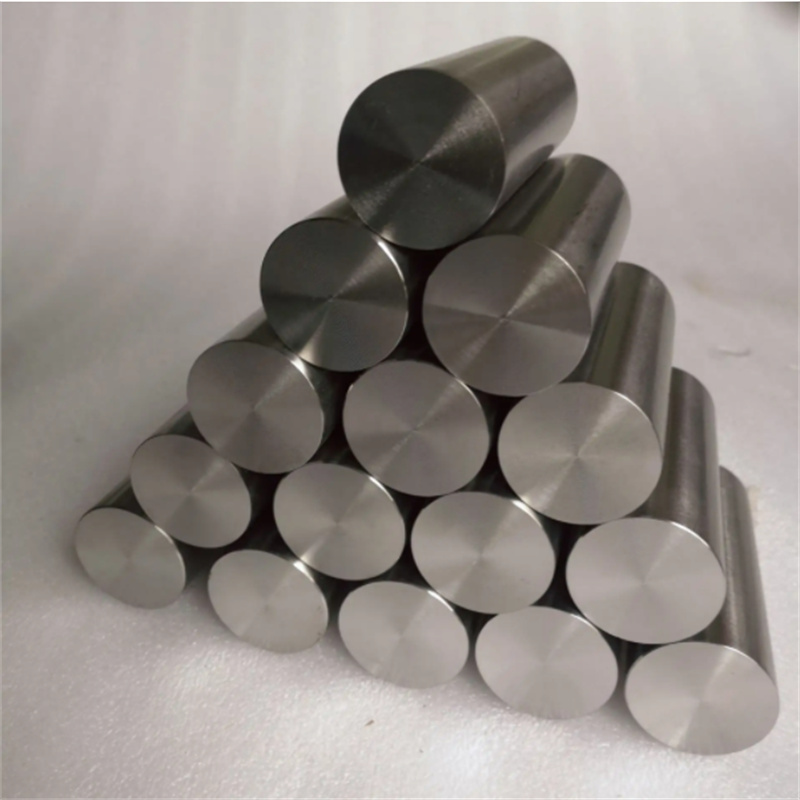

Shengliheng (Ningxia) Vacuum Technology Co. , Ltd. is located in Shizuishan High-tech Development Zone, Ningxia. Is a research and development, production, sales as one of the national high-tech enterprises. The company's existing R & D personnel are all senior engineers with the title of technical personnel. The company is specialized in the research, development and manufacture of various types of new functional materials for high temperature and high vacuum sintering furnace. Through independent research and development, has obtained the National Authorization Invention Patent 4, the utility model patent 15, the Outward Appearance Patent 2. At the same time, through the SGS Quality Management System Certification. In just a few years, the company has provided high-end vacuum sintering equipment to institutes of higher learning in more than a dozen provinces and cities across the country, and provided technical services to well-known domestic universities including Fudan University, Tongji University, Harbin Institute of Technology, etc. , it has provided production and R & D Equipment for the Shanghai Institute of Silicates, the 13th Institute of Electronics, the China Research Center of the Ukrainian Institute of Materials, the Antai Institute of Science and Technology, etc. , in particular, the vacuum of the equipment manufactured for the Shanghai Silicate Research Institute has reached 3.3E-8, the first set of products from the autonomous region has been approved, the first set of equipment from the state is being declared, and the company has taken the lead in setting up the first shared workshop in Ningxia, it provides strong support for the cultivation of high-skilled talents in Ningxia. In 2016 the company's products were certified by the Ministry of Science and technology to reach the international advanced level, also passed the Swiss SGS product quality certification, intellectual property rights consistent Mark Certification. In 2020, the company's annual sales reached more than 20 million yuan. $1.84 million in taxes. We have purchased 33 mu of land and invested 80 million yuan to carry out the industrialization project of high temperature and high vacuum sintering furnace equipment with an annual output of 1000 tons of special titanium alloy materials and special materials. By the end of 2021,33 Mu of land had been purchased for the new project, with more than 6,500 square meters for the first phase of construction and 7,000 square meters for the second phase.