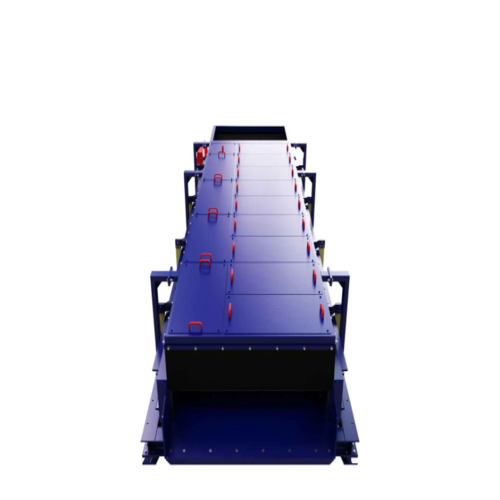

Screening crusher CR600, crusher

Sandvik screening crusher

Sandvik's screening crusher combines innovative design with advanced technology. The compact design of the machine has extremely high material handling capacity, which greatly facilitates the overall layout design of the crushing and processing workshop, and can significantly reduce the size and floor space of the workshop, thereby reducing investment costs.

Feed material

Sandvik CR610 and CR620 screening crushers are widely used for primary, secondary and tertiary crushing of lignite, coking coal and other similar low to medium hardness raw materials.

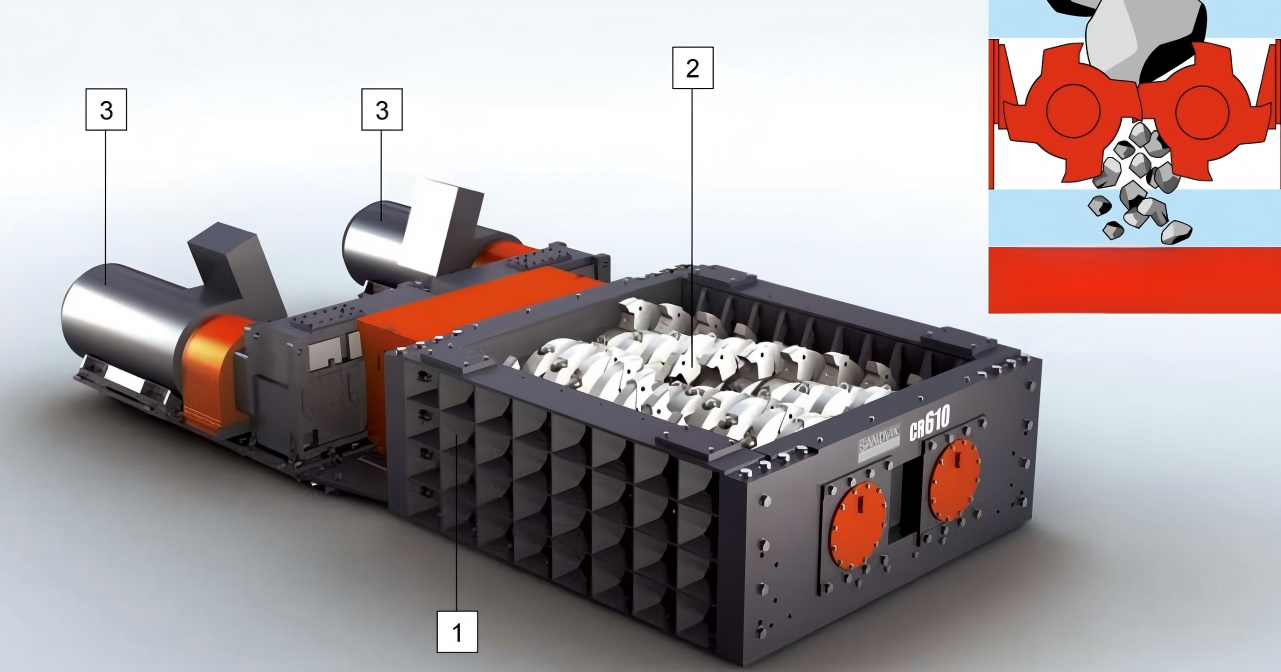

Working method

In the primary crushing stage, the material passes through the counter-rotating crushing rollers of the CR610 screening crusher to initially reduce the size of the feed.

The crushing bars attached to the bottom can also assist in the crushing process.

The CR620 type screening crusher with two-side feed is used in the second and third stages of crushing. The material passes between the outward rotating crushing rollers and the toothed wear plates on both sides. The shear and tension forces generated by the low speed and high torque of the crushing rollers will further process the material size. When choosing a suitable type of screening crusher, the criteria mainly depend on the technical parameters required, such as material properties, feed material size, desired discharge size and output, while investment and operating cost factors must also be considered.

Parameter Specifications

Feed material size: up to 2000 mm (79 in)

Discharge size: minimum less than 40 mm (2 in)

Processing capacity: up to 6000 mtph (6614 stph)

Crushing ratio: 1:3~1:10

Installed power: 2 x 800 kW (1073 hp)

Packing & Delivery

Established in1998,Ningxia Security Mechanical& Electrical Engineering Co..Ltd. It is a company with qualifications for the production and maintenance of China's coal mine equipment flip-flow screen, centrifugal machine and crusher. The company is located on the 11th floor of Xinlei Building, No. 148 of Zhongxin Lane, Xingqing District, Yinchuan City, Ningxia Province. It obtained the import and export authorization from government in 2006. And since 2012, the company exclusively sold "Saitelite" brand polyurethane screens, with more than 2,000 square meters of Production maintenance workshop.

Since the establishment, the company has been implementing the managing philosophy of "trusted by honesty, established by virtue, and win by quality". it has been awarded the Western Development Excellent Enterprise and the integrity Enterprise etc.from 2002. Since 2006, it is kept being awarded the Observing Contact and Emphasizing Credit enterprise in Ninxia as well as Yinchuan.

Nowadays,the company has built long-term stable partnership in business with a wide batch of key enterprises including ShenHua Group, China National Coal Group Corp,Shaanxi Coal and Chemical industry Group Co. Ltd.Lu’An Group. GuangHui Group,Yunnan XianFeng Group.China Guodian,QingHua Group, Hebei Fengfeng Coal Group,and ZhongYan Group etc. and built solid foundation for the China colliery industry in terms of development on fine screen and crushing with independent, dedicated and outstanding ability.

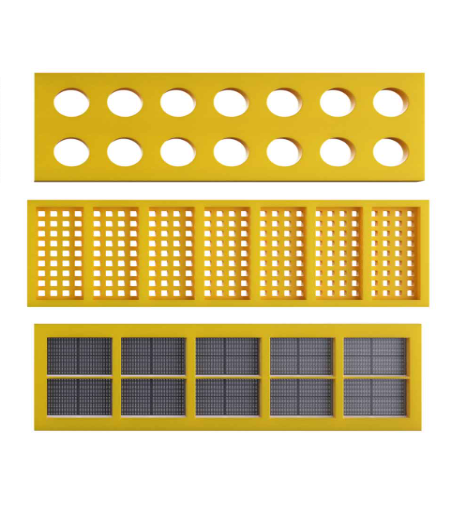

One-stop service provider for screening, separation, and crushing

Our company is based in Yinchuan, Ningxia, with a satellite office in Beijing. We own office buildings, assembly and maintenance workshops, warehouses, and other properties. Since our establishment in 1998, we have primarily been engaged in the agency sales of German LIWELL® flip-flow screening machine and related accessories, Australian TEMA centrifuges and accessories, and Tianma Xibo polyurethane screens and accessories. The company holds qualifications for the maintenance of flip-flow screening machine, centrifuges, and crushers for Chinese coal mining equipment, as well as the import and export rights of mechanical and electrical equipment, and ISO9001 quality system certification. We have established a comprehensive and continually deepening model of efficient operation, consistently reinforcing our position in the finer screening, materials separation, and crushing industries.

Service Domains

Committed to delivering high-quality and comprehensive screening, separating, and crushing solutions for industries such as coal, chemical, metallurgy, sand and gravel, solid waste treatment, etc.

Dedicated to industry value creation and earning customer trust.

Technical Capability

To ensure a continuous delivery of high-quality equipment and solutions within the industry, we have collaborated extensively with foreign professional equipment manufacturers and the State Key Laboratory of China University of Mining and Technology.

The collaborative achievements have been honored with various awards, including the first and second prizes of Science and Technology Progress Award of China Coal Industry Association, and the acquisition of seven technical patents from the National Patent Bureau.

Service Capabilities

Ningxia Security Mechanical & Electrical relies on an efficient and mature operational management model, a strong supplier network, and a complementary self-owned maintenance warehouse base to ensure timely and high-quality completion of every order. Our professional technical team offers post-sales services which serve as reliable support for your production. In addition to providing essential spare parts and personnel services, we collaborate with you to develop tailored maintenance and service plans, guaranteeing maximum equipment availability. Therefore, our services encompass four fundamental modules: Spare Parts Availability, Localized Service, Preventive Maintenance, and Overhaul Prevention.