The silicon metal is manufactured with carbon type reducing agent and silica while silica is melting in furnace.It is mainly used in production of alloys (especially aluminum alloys), polycrystalline silicon , organic silicon materials and high-grade refractory material.

It is Silver gray or dark grey powder, Heat-resistance and good performance.The Silicon metal possesses quite widely. For example, to produce organic-Si(Si-oil, Si-rubber) etc in chemical industry. And also regarding the no-ferroalloy’s additive, deoxidize, silicon-steel etc alloys adding materials. It’s applied to mechanical, chemical, alloys, electronic, medicine industry etc.

Specification :

Grade | Chemical Element (%) | |||

Si | Fe | Al | Ca | |

553 | 98.5%min | 0.5%max | 0.5%max | 0.3%max |

441 | 99%min | 0.4%max | 0.4%max | 0.1%max |

3303 | 99%min | 0.3%max | 0.3%max | 0.03%max |

2202 | 99%min | 0.2%max | 0.2%max | 0.02%max |

1101 | 99%min | 0.1%max | 0.1%max | 0.01%max |

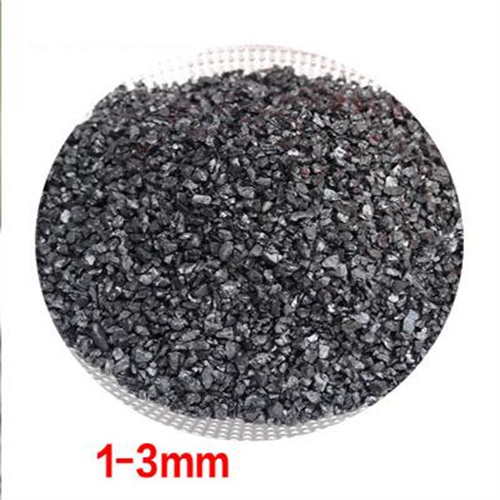

Size of product : 10-50mm , 50-100mm , 50-150mm .

Application:

1) Widely applied to refractory material and power metallurgy industry to improve the heat resistance, wear resistance and oxidation resistance.

2) In the chemical line of organic silicon, industrial silicon powder is basic raw material that high polymer of organic silicon formatting.

3) Industrial silicon powder is sublimated into monocrystalline silicon, which is widely used in highttech field as an essential raw material for integrated circuit and electronic element.

4) In metallurgy and foundry line, industrial silicon powder is regarded as to be iron base alloy additive, the alloy pharmaceutical of silicon steel, thus improve the steel hardenability.

5) These are used in high-temperature material production in order to manufacture enamels and pottery. These also cater the demands of semiconductor industry by producing ultra-pure silicon wafers.

Package & Transport :

As normal , we packed in 1000KG as one bags and loading 25MT in each container by sea .

We can supply sufficient Graphite petroleum coke annual production in 40,000 tons, Semi calcined petroleum coke annual production 80,000 tons and anthracite based carbon additive annual production in 150,000 tons. Special particle size is available for your requirements. Our factory has a complete quality system supervision system . It proceeds as raw material analysis , process supervising , final product inspection , perfect package assurance and close delivery tracking . Batch management and process quality control is strictly carried out throughout the production . Nowadays , our products have been export our products to USA, Korea, Japan, South Africa, Indonesia, India and etc.

NINGXIA CARBONHEL NEW MATERIAL CO.,LTD main produce and supply different kinds of recarburizer and ferro alloys for ductile iron, steel making, casting and foundry industry. Main products including anthracite based carbon additive(GCA/CAC), calcined petroleum coke(CPC), graphitized petroleum coke(GPC) and ferro alloys. These products are widely used in metallurgy, chemical industry, steel-making, casting industry and many fields. We have mature production line, professional sales team and best after sales service to supply the best quality products to customers.

Our factory is in Shizuishan Ningxia which located in Helan mountain and rich in high quality Taixi anthracite . The superior geographical location provides us with high-quality raw materials . Therefore , Quality first is our belief, service is our guarantee. We can supply sufficient Graphite petroleum coke annual production in 40,000 tons, Semi calcined petroleum coke annual production 80,000 tons and anthracite based carbon additive annual production in 150,000 tons. Special particle size is available for your requirements. Our factory has a complete quality system supervision system . It proceeds as raw material analysis , process supervising , final product inspection , perfect package assurance and close delivery tracking . Batch management and process quality control is strictly carried out throughout the production . Nowadays , our products have been export our products to USA, Korea, Japan, South Africa, Indonesia, India and etc.