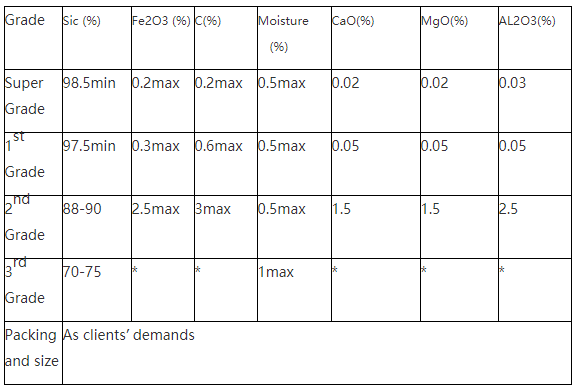

Black Silicon carbide Grain is an extremely hard and 99% SiC carborundum grit. As an abrasive material, it can work well for abrasive blasting, surface treatment, grinding on hard material such as marble, glass, jade, etc. Silicon Carbide is produced by a process involving the electrochemical reaction of silica(SiO2)-in the form of quartz mixed with Carbon(C) in the form of raw petroleum coke. The stoichiometric mixture is reacted in an electrical resistance furnace at a temperature up to 2500 centigrade to yield high-quality crystals. The process is large furnace technology with a graphite electrode in the furnace center. The large crystals are then segregated, crushed, cleaned of magnetic impurities in high-intensity magnetic separators, and classified into narrow size fractions to suit the end-use. Dedicated lines produce products for different applications.

NINGXIA CARBONHEL NEW MATERIAL CO.,LTD main produce and supply different kinds of recarburizer and ferro alloys for ductile iron, steel making, casting and foundry industry. Main products including anthracite based carbon additive(GCA/CAC), calcined petroleum coke(CPC), graphitized petroleum coke(GPC) and ferro alloys. These products are widely used in metallurgy, chemical industry, steel-making, casting industry and many fields. We have mature production line, professional sales team and best after sales service to supply the best quality products to customers.

Our factory is in Shizuishan Ningxia which located in Helan mountain and rich in high quality Taixi anthracite . The superior geographical location provides us with high-quality raw materials . Therefore , Quality first is our belief, service is our guarantee. We can supply sufficient Graphite petroleum coke annual production in 40,000 tons, Semi calcined petroleum coke annual production 80,000 tons and anthracite based carbon additive annual production in 150,000 tons. Special particle size is available for your requirements. Our factory has a complete quality system supervision system . It proceeds as raw material analysis , process supervising , final product inspection , perfect package assurance and close delivery tracking . Batch management and process quality control is strictly carried out throughout the production . Nowadays , our products have been export our products to USA, Korea, Japan, South Africa, Indonesia, India and etc.