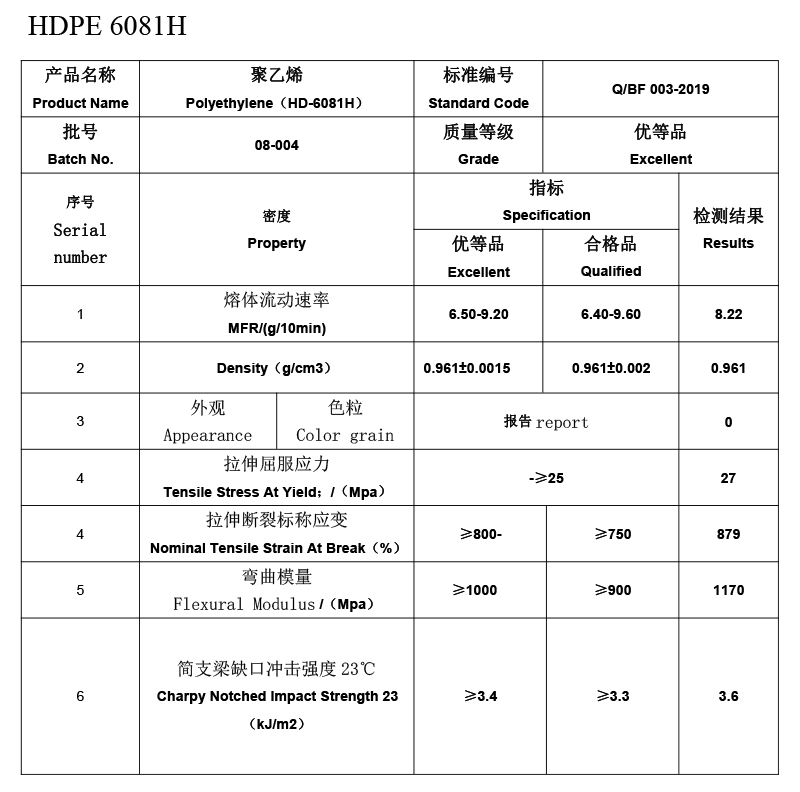

HDPE 6081H Advantages: Low pressure injection plastics produced using chevron Phillips Chemical's proprietary MarTECH ADL advanced double ring process. The product has excellent air tightness, high impact strength, high hardness, excellent ductility, good static resistance, excellent thermal forming, good product stability, good heat resistance, acid and alkali resistance, impact resistance and extrusion resistance.

Details Images

Certifications

Packing & Delivery

Company Profile

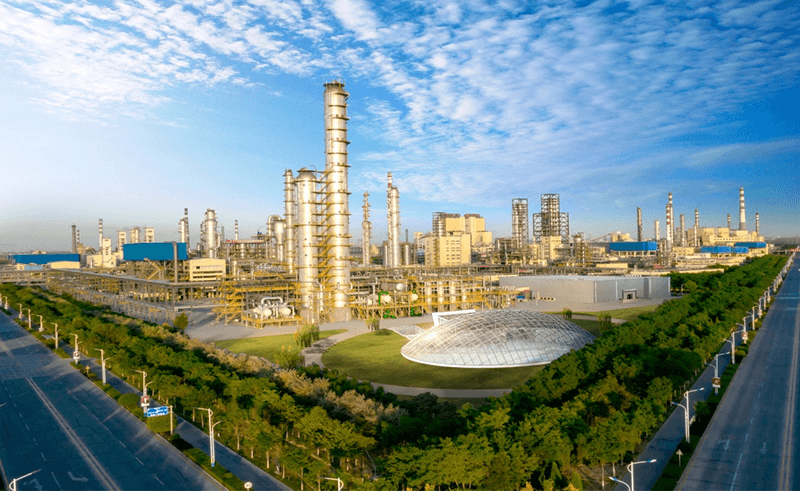

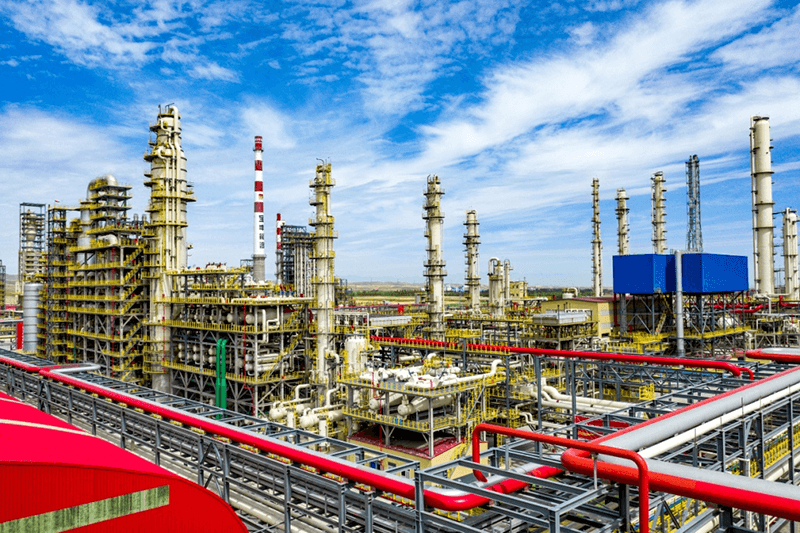

Ningxia Baofeng Energy Group Co., Ltd was established in November 2005, listed on the A-share main board of the Shanghai Stock Exchange in May 2019 (stock code 600989), with nearly 16,000 employees. The company has grown into one of the most advanced coal-based new material producers in China, and a pioneer in the new energy industry.

The company actively responds to propose of the national strategy, adheres to scientific and technological innovation, inherit the green and sustainable development concept of "resource conservation and environmental friendliness". The company invested 72.7 billion yuan to build a 2306-acre "advanced coal-based new material circular economy industrial park" in the core area of the national Ningdong Energy and Chemical Base, which has formed the largest circular economy industrial cluster integrating of coal, coke, gas, methanol, olefins, polyethylene, polypropylene, fine chemicals, and new energy. which could take fully and efficiently advantage of coal resources.

The company innovated the process route and built the world’s largest single-unit capacity and single-plant scale "solar electrolytic water producing hydrogen project", using solar energy to generate "green electricity" and produce "green hydrogen" and "green oxygen", becoming the world's largest green hydrogen production plant and the world's largest supplier of green hydrogen. The “green hydrogen” and “green oxygen” are directly supplied to the chemical system to realize the coupled development of new energy and coal chemical industry, creating a technologically advanced and economically feasible “carbon neutral” scientific path in the industry. The company has the capability to substitute petroleum by coal and substitute fossil energy by new energy for producing nearly a hundred advanced chemical products. Furthermore. The company fully fills the gap in domestic imports, actively safeguarding national energy security, and set a benchmark for the high-quality development of the industry, devoted to create a technologically cutting-edge, industry-leading, world-class technology-based green manufacturing enterprise.