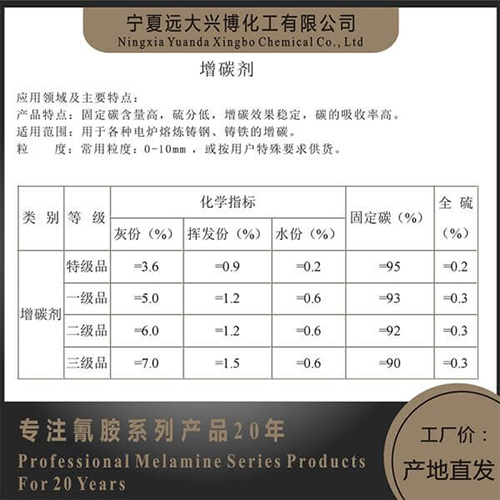

Name | Carburant |

Product Feature | High fixed carbon content, low sulfur content, stable recarburization and high carbon absorptivity |

Application Scope | Used for recarburization of electro-smelting steel casting and iron casting Particle Size: Common Used Particle Size: 0-10mm, or customizable |

Usage | 1) Adjust the carbon content during preparation, add the carburant into lower middle part of an electric furnace together with metal furnace burden according to the requirement of carbon content during steel (iron) liquid melting, do not stir slag while the carburant is melting, otherwise the carburant will be mixed in the waste slag and then carbon absorption is influenced. The carbon absorption rate can reach 90%-95%. 2) Adjust the carbon content after steel (iron) is melted, wherein the carburant can be added on the surface of the steel (iron) liquid and carbon will be dissolved and absorbed through eddy stirring or manual stirring of the steel (iron ) liquid during electro-smelting. The carbon absorption rate can reach 90%-95%. |

Specifications and Items | |

Usage |

| Grade | Fixed Carbon (%) | Total Sulfur (%) | ||||||||||||||||||||||||

Carburetting agent |

|

|

|

| ||||||||||||||||||||||||

Carburetting agent

|

| Extra Grade Products | ≥96 | ≤0.1 | ||||||||||||||||||||||||

(Electric Calcined Material) |

|

|

|

|

Application

Proper use of carbon additives in induction furnace

Aa. Using electric furnaces of more than 5T, the raw material is single and stable, and we recommend the decentralized addition method.According to the requirement of carbon content, according to the proportion of ingredients, the carburizer and the metal burden will be added to the lower part of the electric furnace together with each batch of materials. The carbon absorption rate of one layer of metal burden and one layer of carburizer can reach 90% to 95%.

Bb. The medium frequency induction furnace with about 3T is used. The raw material is single and stable.When first melting or leaving a small amount of iron water in the furnace, the carburizer that needs to be added shall be added to the surface of iron water at one time, and the metal burden shall be added immediately.

Cc. Using small medium frequency electric furnace with raw materials containing high carbon substances such as pig iron, we recommend fine tuning of carbon adding agent.After the steel/iron water is melted, adjust the carbon content, which can be added to the steel/iron water surface. The product can be dissolved and absorbed by eddy stirring of steel (iron) water or manual stirring during smelting in electric furnace. The carbon absorption rate is about 93%.

We are based in Ninxia, China, start from 2007,sell to North America(50.00%),Eastern Europe(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Asia(5.00%),Mid East(5.00%),Oceania(5.00%),Africa(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Biological product,Chemical additives,Agar powder,Cysteamine Hydrochloride,HPMC

4. why should you buy from us not from other suppliers?

null

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,PayPal,Western Union;

Language Spoken:English

Packing & Delivery:

Product packaging: polypropylene woven bag plus inner membrane packaging, 50kg small bag and 1000kg large bag, which can also be packaged according to customer requirements.

Ningxia Yuanda Xingbo Chemical Co., Ltd. is a comprehensive chemical production enterprise integrating r&d, production and sales. The company's products include: carburizer, calcium carbide, lime nitrogen, particle lime nitrogen, dicyandiamide, electronic grade dicyandiamide, ultrafine dicyandiamide, guanidine nitrate, airbag special ultrafine guanidine nitrate, and the development and production of new ultrafine chemical materials. Over the years, the company has strengthened the introduction and absorption of advanced technologies at home and abroad, advocated the development concept of independent innovation, and the enterprise has developed rapidly, from the basic chemical raw material production to the production of fine chemical products, and from the production of fine chemical products to the production of high added value of ultra-fine chemical new materials.

The company has been adhering to strict management, adhere to the "people-oriented, strive for first-class; Win by quality, credibility first "quality policy.

Yuanda Chemical takes the general customers as the foundation, provides the excellent service as the tenet, wholeheartedly provides the high quality product and the more excellent service for the general customers. We look forward to cooperating with you sincerely.