Product description

Silicon Carbide Sand/Granular

Silicon Carbide Sand/Granular

Rongchang silicon carbide sand is produced using black silicon carbide blocks through a series of processes such as crushing, shaping, pH testing, magnetic separation, and screening, and has a variety of particle sizes.

This silicon carbide has the characteristics of regular particle shape, clustered particle size, high bulk density, and high particle surface cleanliness.

1. This product is produced in accordance with the international standard GB/T2481.1-GB/T2481-1998 and compatible with European FEPA and American AIVSI standards.

2. Granular sand and refractory sand with different bulk density can be processed according to customer requirements.

Product Usage: Used to make Grinding Wheels, Cutting Blades, Wear-Resistant and Corrosion-Resistant Materials, FRP Pipes, Blasting Sand and Casting Materials, etc.

Silicon Carbide Powder

Rongchang Silicon carbide powder is a silicon carbide powder product of more than 100U formed after being crushed by the raw silicon carbide by Raymond machine, jet mill, ball mill, and shaping machine, and then classified into products of different international standards by overflow method.

Its air particle hardness can reach 2800-3300KG/mm². High purity, low impurity content, high cleanliness of particle surface, and particle size clusters.

Product Usage:

1. It is an important raw material for manufacturing high-grade refractory materials, high-temperature ceramics, resistance heating elements, abrasives and recrystallized silicon carbide products.

2. Various types of ultra-fine silicon powder crushed and classified by jet mill will achieve ideal results in ultra-fine grinding and polishing.

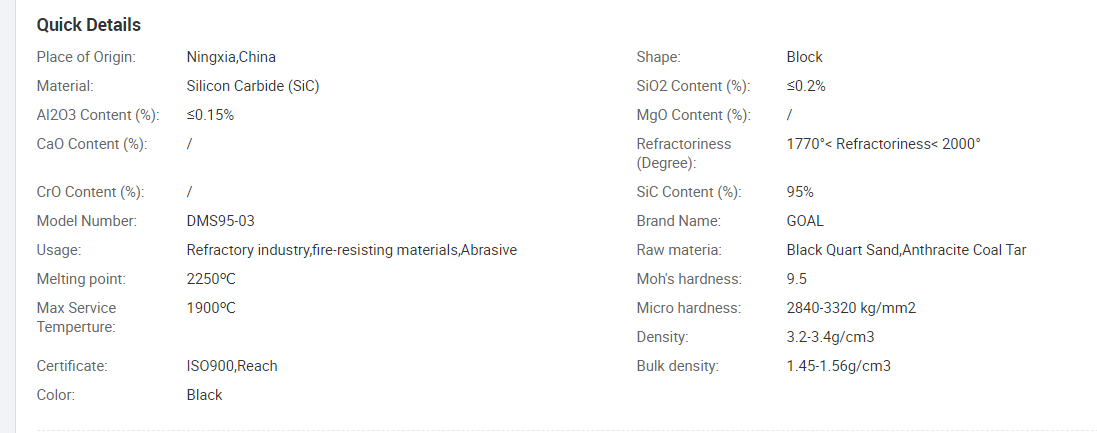

Silicon Carbide Block

Black silicon carbide, with metallic luster, has a molecular formula of SiC and contains about 98.5% of SiC. Its toughness is higher than that of green silicon carbide. It is made from quartz sand and anthracite as the main raw materials and smelted at high temperatures in a resistance furnace.

It is a black opaque body, hexagonal crystals, with a Mohs hardness of 9.15-9.5, which is higher than corundum in abrasives and second only to diamond and boron carbide.

High mechanical strength, stable chemical performance, high thermal conductivity, low thermal expansion coefficient, good wear resistance, and certain electrical and thermal conductivity.

Rongchang silicon carbide block uses high-quality anthracite and high-purity quartz sand from Helan Mountain in Ningxia as raw materials, uses a large resistance furnace body, and uses high-power smelting technology to produce high-purity, large-crystalline black silicon carbide. Its crystallization is more complete and the product is The physical and chemical indexes and performance are significantly higher than those of general products.

Product Usage: Used for making abrasive tools and processing metal and non-metal materials with low tensile strength. Such as: gray cast iron, glass, ceramics, stone, refractory materials and non-ferrous metals.

Finished product 1 - Silicon Carbide Sand/Granular

Finished product 2 - Silicon Carbide Powder

Finished product 3 - Silicon Carbide Block

- Packaging Details

- Standard export packing, or required by customer

1.25Kg/Bag

2.Ton Jumbo Bag, 18 Tons/20' Container

3. Bulk in Container, 20-21Tons/20' Container4.As customers' request

Delivery Method: Support FOB, CIF and CFR method, The specific is selected according to your needs and actual conditions

Pingluo county for prosperity of silicon carbide co., LTD founded in 2004, is a comprehensive private enterprise integrating silicon carbide production, processing and sales. The company is located in Ningxia Pingluo Industrial Park, covering an area of 73000 square meters, with fixed assets of more than 120 million yuan. The company has more than 200 employees and more than 20 technicians.

The company mainly produces various specifications of black silicon carbide, with an annual output of more than 35000 tons of silicon carbide and a set of 32000kva silicon carbide smelting furnace. At present, we have domestic advanced silicon carbide production line and process technology, established standardized quality inspection department, and established ISO9001 quality management system to provide strong guarantee for product quality control. In line with the business philosophy of green development, the company invested more than 35 million yuan to upgrade the environmental protection of the whole set of smelting furnace, reaching the advanced level of environmental management, energy consumption management and safety management.

The company adopts advanced silicon carbide smelting technology and advanced energy-saving equipment at home and abroad, uses Ningxia Helanshan high-quality anthracite and high-purity quartz sand as raw materials, uses large resistance furnace body, adopts high-power smelting technology, and produces high-purity and large crystal black silicon carbide, which makes silicon carbide crystal more complete, and the physical and chemical indexes and service performance of the product are obviously higher than ordinary products.

Due to the stable process characteristics of the high-power resistance furnace, the self-regulation performance of the furnace body is good, and the single furnace output reaches 1500 tons. Since it was put into operation, the product quality, output and performance have been greatly improved, and the superiority of the product has been recognized and used by many companies at home and abroad.

After more than ten years of hard work and continuous development, the company has become a large modern enterprise with modern management level, perfect management system, advanced technology and strict quality control system. Guided by the spirit of "people-oriented, win-win cooperation", the company has gradually achieved the development goals of industrial specialization, product serialization, diversified operation and market internationalization. Its products are exported to Europe and the United States, Japan, South Korea and Southeast Asia and many other countries and regions, are widely used in steel, ceramics, refractories, kilns, non-ferrous metals, power electronics, abrasives, aerospace and military and other high-tech fields, enjoy a high reputation at home and abroad. The company adheres to the enterprise tenet of "excellent quality, reputation first", and sincerely cooperates with new and old customers at home and abroad for common development with high-quality products and perfect service!