The specific process flow of electrode paste is as follows:

1. Pretreatment and calcination of raw materials:

The physical and chemical indicators of the electrode paste depend to a large extent on the raw materials used. If the origin of similar materials and the preparation method are different, the quality of the finished products also varies greatly. Therefore, the raw materials must be selected correctly to produce the technical indicators The required electrode paste. The main raw materials of electrode paste products are petroleum coke, anthracite, residual poles, graphite crushing, metallurgical coke and coal pitch, etc. In the selection of raw materials, the raw materials must be pretreated first, mainly referring to the selection of massive residual poles and surface impurities Cleaning, drying of metallurgical coke powder, melting dehydration of coal pitch, etc.

In addition, in order to improve the performance of roasted products, the raw materials for preparing electrode paste are generally required to be calcined, mainly the calcination of petroleum coke and anthracite. Calcination is the high-temperature heating treatment of various solid carbonaceous materials under the condition of air isolation. It is An important process in carbon production.

Due to the difference in coking temperature or geological age of various solid raw materials (such as petroleum coke, pitch coke, anthracite, metallurgical coke, etc.), the internal structure contains moisture, impurities or volatiles to varying degrees. If these substances are not excluded in advance, directly using them to produce carbon graphite materials will inevitably affect product quality and performance. It is petroleum coke and anthracite that are largely calcined in carbon production enterprises. Various carbon raw materials have produced a series of changes during the calcination process. In summary, there are the following changes: remove from raw material of volatile component, moisture, accelerate the change of sulfur content in the material so as to control the ash content increased, make the focal volume shrinkage and become stable, so, to improve the raw material of true density, strength, electrical conductivity and oxidation resistance.

2. Crushing and screening of raw materials:

Before mixing, kneading and forming, the electrode paste raw materials must go through important steps such as crushing, grinding and sieving to obtain the carbon particles of various particle size and purity required for the production of electrode paste. Usually the solid materials are crushed by large pieces The operation of breaking into small pieces is called crushing, and the accuracy of the size and number of carbon particles has a great influence on the performance of the electrode paste. Therefore, the raw materials must be crushed and sieved into various particle size levels before the ingredients can be used.

In the production of carbon graphite materials, the formula for the particle size of the raw material is the close-packed principle, that is, the unit volume reaches the maximum density. When the raw material is crushed, the crushed product is composed of various particle sizes that are not in specifications. Ideally, the particle size distribution should be normal Distribution, but in actual production, the particle size distribution of the crushed product is segregated, which is a non-normal distribution. Therefore, after the general raw material is crushed, the particle size of the product cannot be the various particle sizes we need. In addition, different varieties of products have different requirements for particle size. Even for the same product, different specifications of products have different requirements for particle size. Therefore, in production, according to the variety and specifications of the product, from the broken product Sieve out the required particle size. In the production of carbon, the method of sieving is often used to divide the crushed materials into different particle grades. To obtain products with good quality and stable performance, the use of suitable crushing machinery and sieving machinery is an important part of the production of electrode paste. The link is also the main preparation process.

3. Grinding of carbon raw materials:

The grinding system is generally composed of a grinding machine, a blower, a feeder, a separator (such as a cyclone separator), a storage hopper, a silo, and a dust removal system. The material is fed into the pulverizer through the feeder, and the ground material is brought out of the airflow blown by the blower into the separator (analyzer), and the coarse material that does not meet the requirements is separated into the mill and then ground. The material that meets the requirements enters the cyclone separator along with the airflow, and separates the fine powder that meets the requirements from the airflow and enters the silo.

4. Formulate the product;

The structure of carbon graphite materials and products belongs to the structure of powder particles. It is through a certain process operation to make the carbon particles and powder and the binder carbon pass through the chemical bonding force, intermolecular force, mechanical adhesion force and mechanical inlay bite force, etc. The comprehensive effect of the formation of a uniform whole with a certain shape and function. The structure and performance of this powder depends on factors such as the concentration (proportion) of various powders, the size of the surface shape and surface area, and their mutual configuration. If these materials with different structures and properties are mixed in a certain proportion and mixed thoroughly to form a uniform whole, a new material with comprehensive properties that is completely different from the raw materials can be obtained. It can be seen that in order to prepare new materials with the required structure and performance, it is meaningful and valuable to select the appropriate raw materials, the particle size of the raw materials and their proportioning. This is the purpose of the formula.

The formulation of electrode paste formulation mainly includes: batching and weighing, selection of suitable raw materials, powder mixing and particle size determination, binder dosage determination, production return material recycling, etc.

The so-called "recipe" refers to the preparation of a certain proportion (or the list of ingredients) of a number of solid raw materials with different properties and particle sizes and the binder, referred to as the recipe. According to the conditions of use, carbon products are required to have a variety of performance. For this purpose, it is necessary to select various raw materials according to the performance, and to adjust the amount and particle size between them, so that the characteristics of various raw materials can be used in the products. So as to achieve the performance required by the product. Combining one or several solid materials with different properties and different particle sizes and binders in a certain proportion, this process is called batching.

When formulating the formula, the types of raw materials should be reasonably selected according to the use and specifications of the product, and the optimal ratio and the optimal particle size ratio should be formulated to achieve the optimal organizational structure of the product. According to the type of raw materials, particle size ratio and surface properties of the powder, the appropriate binder and its ratio should be selected so that the powder particles of the product have the best bonding performance.

Although many researchers have conducted many studies on the theoretical calculation of the formula and summarized some theoretical formulas, they have not been able to obtain satisfactory results with the formula calculation. The current production formula is gradually summarized through long-term production practice. Carbon production has a strong experience. Therefore, to formulate a new formula, it is better to use a combination of theoretical calculation and experiment. Theoretical calculations can make the experiment organized and systematic, so that the experiment will not be disoriented, but it must be repeated practice, and summary and change to determine the best formula. In addition, in actual production, when the raw materials used change, the particle size composition of the aggregate and the type and amount of binder should also be adjusted accordingly. If the production process, equipment, etc. change, the formula should also change accordingly.

The formulation of electrode paste products mainly refers to the combination of dry materials, which is an important part of the formulation of electrode paste. What raw material is selected as a fine powder has a direct impact on the quality of electrode paste. The large, medium, and small particles in the aggregate should be reasonably matched to increase the bulk density, and the purpose of controlling the particle size composition is to obtain dense, high-strength, and good conductivity self-baking electrodes after firing. The amount of powder added should match the amount of binder added, so that the plasticity of the electrode paste is within a specified range, which can not only merge with each other and fill the entire electrode cylinder, but also do not cause delamination due to too easy flow. If the amount of binder is too much, the electrode paste sintering speed can not keep up with the consumption speed, it is easy to break, not easy to sinter, and easy to produce solid particles and adhesive layering phenomenon. If the amount of binder is low, and the electrode paste is sintered too fast, over-baking will occur, which will make the binding force between the particles poor, the density is poor, the porosity is high, the strength is low, resulting in easy oxidation, high consumption, and electrode hard accident.

5. Product mixing process:

When producing electrode paste products, various carbon materials (granular materials and powder materials) and binders are stirred and mixed at a certain temperature and time to form a plastic paste. This process is called kneading. The mixing and kneading must be carried out at a certain temperature and maintaining sufficient mixing time. The mixing and kneading is divided into two steps: dry mixing and wet mixing. Dry mixing is also called mixing. The main purpose is to make the solid carbon materials of different particle sizes uniformly mixed and filled to improve the mixing The bulk density of the material and heat the material to a temperature close to the binder, evaporate a small amount of internal moisture contained in the raw material, and enhance the wettability with the binder. The purpose of wet mixing is to make the binder evenly coat and infiltrate the surface of the carbonaceous particles, and absorb a layer of "adhesive film" on the surface of all carbonaceous aggregates and powders, relying on the binding force of the binder to connect all the carbonaceous materials to each other. It sticks together to give the paste a certain plasticity, so that it can be cured at room temperature to form. At high temperature, the volatiles evaporate, and the polymer polycondensation and coking form a "coking film", which improves strength, increases compactness, and reduces resistivity.

6. Product molding process:

The paste prepared by kneading or the powder pressed and mixed dry powder has not yet fixed shape and size, nor has it reached a higher bulk density, nor overall strength. In order to obtain a certain shape, size, density and mechanics For carbon products with good quality, the kneaded paste must be molded. The so-called "molding" is to mix the kneaded paste or powder into a block (rod) object with a certain shape, a certain size, a certain density and mechanical strength in a mold by a certain method and a certain pressure Process operation.

As a kind of carbon products, electrode paste products have the common points and special features of carbon products. The reason why electrode paste products are special is mainly determined by product performance. The electrode paste is the raw material of self-baking electrodes. The roasting process is completed in calcium carbide and ferroalloy ore thermoelectric furnace, that is to say, the baking speed and time of electrode paste are changeable, which is determined according to the furnace type, smelting variety, geometry and electrical parameters of the ore thermal furnace. The variability of firing speed and time makes the electrode paste products have various types of volatile content and plasticity. Most electrode paste products have much higher volatile content than ordinary carbon products, which determines that the electrode paste is difficult Use or do not need to use vibration molding and isostatic pressing, mainly using compression molding and extrusion molding. The performance of extrusion molding is basically the same as that of general carbon products. However, due to the continuity and mass production of electrode paste products, domestic well-known electrode paste manufacturers basically adopt mold-like molding. The so-called compression molding refers to the characteristics of molding, not the traditional molding, the pressure is not transmitted by the external pressure head, mainly relying on its own gravity to pressurize the lower electrode paste product, the model is constantly at the bottom Move to form molded blocks.

The advantage of this molding method is that the equipment is simple and easy to repair, the continuous production performance is good, and the size of the molding block is stable and uniform, but its shortcomings are also inevitable. The main disadvantage is that the upper part has certain The connection, the wear of the model and the poor contact result in a certain amount of production. In small batch production, due to the replacement of the product formula, the pressure cannot be continued, which will make the final batch of products poor in molding effect.

If the operation and managers of the ore-heating furnace are superficial about the quality of the electrode paste or the electrode baking is not properly managed, electrode accidents are likely to occur. Only by strengthening the technical force can we correctly analyze the accident effectively, and we can't just take the method of replacing electrode paste to avoid the occurrence of electrode accident. Due to the lack of directionality and scientificity when replacing electrode paste, the effect may still not be seen after replacement, and even more accidents may occur. Therefore, it is very important for the production operation and managers of the ore-heated electric furnace to understand the detection method of the quality of the electrode paste and understand the matching of the furnace type and the electrode paste.

The inspection standards for electrode paste products are shown in the table.

standard number | ||

Sampling method for carbon materials | GB/T 1427-2000 | |

product | Method for determination of ash content of carbon materials | GB/T 1429-2009 |

product | Method for determination of internal moisture in carbon materials | GB/T 24527-2009 |

product | Method for determination of carbon paste volatiles | YB/T 5189-2007 |

product | Roasting method of carbon paste test samples | YB/T 5054-2001 |

product | Method for determination of compressive strength of carbon materials | GB/T 1431-2009 |

product | Method for determination of bulk density of carbon materials | GB/T 24528-2009 |

product | Method for determination of resistivity of carbon materials | GB/T 24525-2009 |

product | Test Method for elongation of electrode paste | YB/T 5289-2001 |

With the continuous development of domestic and foreign mine thermal electric furnaces towards large-scale, high-power, high-efficiency, energy-saving and environmental protection, and reasonable economy, etc., very high requirements are placed on the quality and demand of electrode paste. The development of high-quality electrode pastes with high strength, superior thermal shock resistance, good sintering performance, no flow paste, continuous electrode, energy saving, environmental protection and other properties has also become an important content of electrode paste research. Due to its industry characteristics, the domestic electrode paste industry does not have high requirements for equipment. Most electrode paste companies follow the development model of small enterprises, and they have no requirements and innovations in technology. They only know a few simple formulas and explore based on the actual use effect. During the adjustment, some manufacturers use the raw materials that are available at low prices for matching. The quality of their products fluctuates greatly, and there has always been insufficient quality and excess quality. The company continues to develop high-strength and high-density thermoelectric shock-resistant electrode pastes. It analyzes the performance of existing carbonaceous raw materials in the market, analyzes the performance of calcined samples after mixing and kneading with different raw materials and binders, and conducts raw material addition methods in the production process. Improve, analyze the impact of different technical parameters in the production process on product performance.

The company hires Youming Hu as the chief technical engineer and is equipped with full-time R&D technicians. The company's technical staff have rich experience in the industry. The technical personnel with college education or above account for more than 20% of the total number of employees, and the full-time scientific research personnel account for more than 8%. High-end technical talents with professional knowledge and practical experience. The company has 3 raw material pretreatment workshops, 5 mixing and kneading workshop production lines, and 3 molding workshop production lines. It has domestic advanced electrode paste processing, testing, and experimental equipment, and has the ability to carry out quality upgrades of electrode paste products. The quality requirements of the purchaser.

Youming Hu, a graduate student, graduated from the School of Materials Science and Engineering of Hunan University in 2008 with a bachelor's degree, graduated from the School of Materials Science and Engineering of Hunan University in 2011 with a master's degree in carbon-oriented materials, and was employed in Lanzhou Sunshine Carbon in the same year Co., Ltd. served as the head of the electrode paste product R&D department, responsible for product development, quality supervision, process transformation and technical exchanges. In 2017, he joined Ningxia Baobao Carbon Co., Ltd. as deputy general manager, mainly responsible for product development, quality supervision, process transformation and Technical communication and other responsibilities.

Youming Hu assisted his mentor, Professor Xia Jintong, to apply for the National Natural Science Foundation, with solid theoretical knowledge of carbon materials. Contact and solve various production problems of domestic large-scale and centralized ore-heating furnace customers during work. In recent years, domestic newly constructed large-scale ore-heating furnaces have all participated in technical exchanges and research and development of corresponding products. The electrode paste products used by them are all developed by Youming Hu. They have a significant effect and play a positive role in recycling, energy saving and emission reduction, and increasing output. Such as: Inner Mongolia Junzheng Group 81000KVA calcium carbide furnace and 65000KVA ferrosilicon furnace, Baotou Mingtuo Chromium Co., Ltd. 75000KVA ferrochromium furnace, China Nonferrous Metals Myanmar Co., Ltd. 72000KVA ferrosilicon furnace and Pingluo Wanshun Metallurgical Chemical Co., Ltd. 42000KVA silicon Manganese furnace, etc.

Youming Hu has a solid theoretical basis of carbon and 8 years of practical work experience in the production and use of electrode paste. He is currently an expert in the field of electrode paste in China. He has edited "The Production and Application of Electrode Paste" published by Beijing Chemical Industry Press. Book to fill the gaps in the industry; published "Application Research of Electrode Paste for 75MVA Ferrochromium Furnace" in Ferroalloy Magazine, which has gained wide attention at home and abroad; obtained 10 various patents; participated in the formulation of the electrode paste industry standard (YB/T4448-2014), The Ministry of Industry and Information Technology promulgates and implements this standard.

In 2017, the company established a scientific and technological innovation R&D team with a total of 8 R&D personnel. Youming Hu led the team for R&D work. The company’s R&D team has developed a number of achievements, and has applied for multiple national invention patents and utility model patents. It has been industrialized in our company, and has been well received by customers. Especially the development of high-strength and high-density electrode pastes with resistance to thermoelectric impact has staged achievements. It has been used in Junzheng 81000KVA calcium carbide furnace and 63000KVA ferrosilicon furnace for a long time. The customers praised it and awarded the best quality award in 2018, and achieved good economic and social benefits.

Ningxia Tianbao Carbon Co. Ltd. was registered in 1999 and managed by the controlling shareholder independently in 2011.

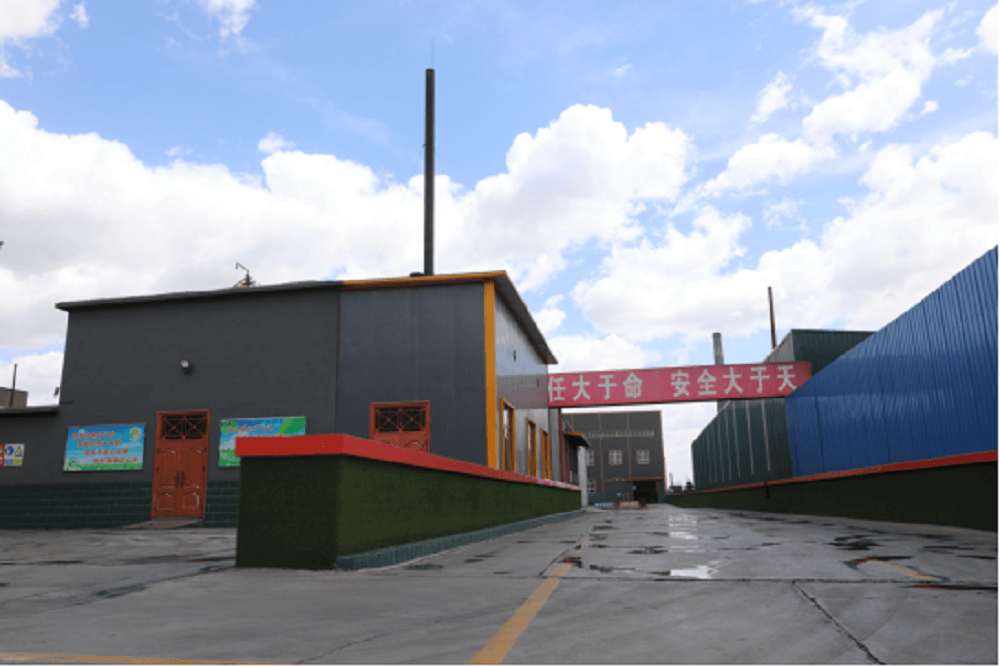

At present, the enterprise has registered capital of RMB 40,018,000 yuan, covers an area of 4,0000.00 square meters, designed annual capacity of more than 200,000 tons, and actual annual operating income of over 100 million yuan. It is one of the influential medium-sized professional carbon manufacturers in northwest China. The company is located in No. 62-1, Coal Middle Road, Changsheng Office, Dawukou District, Shizuishan city, Ningxia, with convenient and smooth transportation. The products can be sent to all parts of the country via Shizuishan freight station, Baolan, Beijing-Tibet Expressway and National Highway 109 and 110.

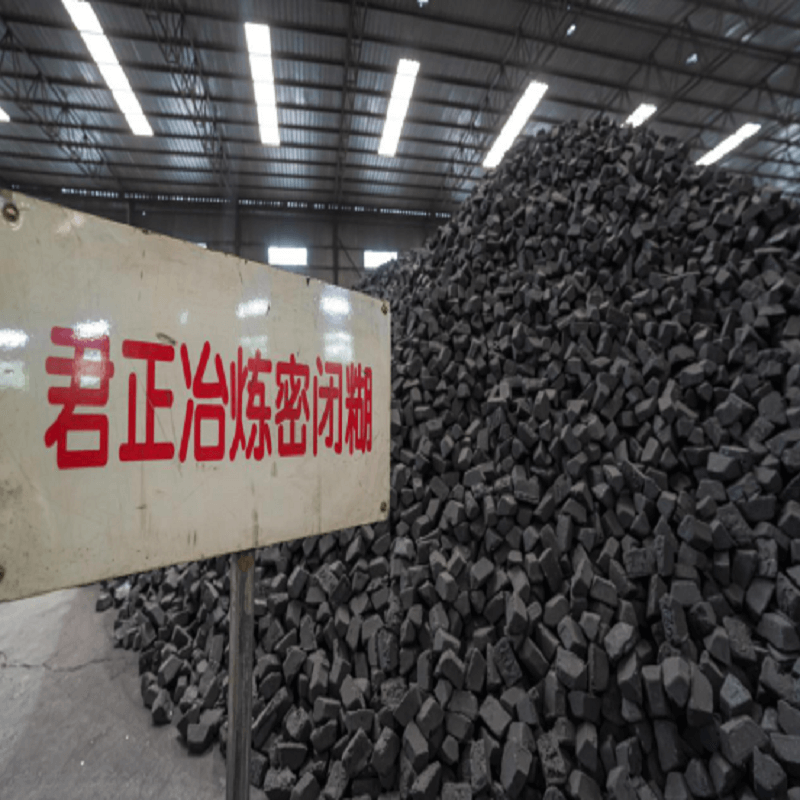

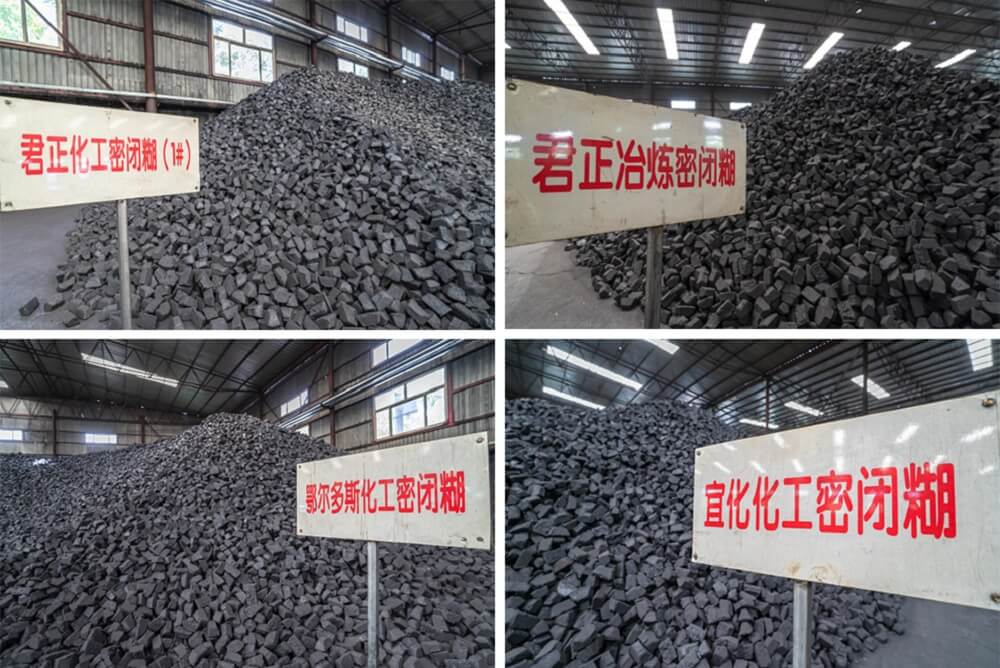

Tianbao Carbon Co. Ltd. is a medium-sized energy-saving self-baking electrode (electrode paste) manufacturer integrating research and development, production, sales and after-sales service. Its products can be used for calcium carbide, nickel, silicon, manganese, chromium and other kinds of mineral thermal electric furnace. At present, the maximum capacity can be used for 81000KVA and 63000KVA super-large ore thermal electric furnaces. Our products are sold to Inner Mongolia, Gansu, Qinghai, Shaanxi, Ningxia and other regions. We have maintained many years of cooperative relations with Inner Mongolia Junzheng, Ordos Chemical, Sinopec Great Wall Energy chemical (Ningxia) Co. LTD., Dongfang Hope Wuhai Zhonglian Chemical Co., LTD., and other large enterprises, and have been highly praised by customers. Company continuously strengthen the quality of the product research and development innovation, set up the enterprise research and development center, established by senior experts from the industry leading professional research team, attach importance to technological innovation, to provide good support for innovation team, continue to implement technology innovation and the innovation technology industrialization, promote the research and development results, improve industry core competitiveness, promote the industry's leading science and technology achievements transformation and application of the promotion. At the same time, we constantly upgrade the technology of production equipment to provide basic guarantee for research and development. At present, we have raw material processing quality control system, fully automatic and closed batching system and complete product quality parameter analysis and testing equipment. Product use high quality raw materials, and constantly improve the advantage of formula and adaptability, to ensure that products in the same industry has a low ash, low resistivity and low sulfur content excellent electrical conductivity, mechanical strength and excellent thermal shock resistance, oxidation resistance and a series of high quality characteristic by the national quality management system certification and apply for the related patent, also get customer for years to use process validation.

The sales management philosophy of "seeking survival by quality, increasing efficiency by research and development, taking sales as the leading and relying on the market" has been an important guideline for the company's survival and development over the years, and is also the specific implementation direction of sales management measures. Advanced equipment, reasonable process, complete testing. It has a first-class postgraduate research team, a mature professional sales team and a perfect after-sales service system. Adhering to the principle of "quality first, reputation first, integrity first", the company will wholeheartedly serve new and old customers at home and abroad for mutual benefit and progress hand in hand.

Company's products stable quality, variety complete, the indicators are superior to national standards, with more than 30 domestic metallurgy, chemical industry, nonferrous metal, carbon enterprises maintained a stable cooperation, company reputation and product quality is highly evaluated by the various customers, product quality qualified rate of one hundred percent and contract execution rate of one hundred percent, user satisfaction rate reached one hundred percent. It has been rated as "honest sodium tax", "advanced Unit", "love to assist the disabled", "keep the contract and honor the credit" by Ningxia Autonomous Region, Shizuishan City and Dawukou District for many times. And with a number of industrial groups to develop into an "excellent strategic partnership."

The enterprise has developed into a backbone enterprise of small and medium-sized scale in Ningxia carbon industry year by year, and has achieved good economic and social benefits, set up a good image of the enterprise, and won the praise of local government and customers. Industrial policies are in line with the positioning of the national energy and chemical industry. We warmly welcome the same industry and love to support the carbon industry friendly people to seek brilliant enterprise development!