Introduction

1. CE qualified

2. High performance

3. Direct sale of factory

4.The compay founded in 1995, has extensive production experiences

Features

Weizheng powder clutches and brakes use magnetic metal powder to transmit torque, which combines the smoothness of fluid clutches and high efficiency of friction disc clutches at clutch/brake engagement. Being a pioneer in the field of powder clutches/brakes, Weizheng boasts of a wide range of products that are suitable for various applications, which have been developed through years of accumulated experience and know-how. Along with their numerous innovative and advanced features, Weizheng's powder clutches/brakes are used as actuators for winding/unwinding systems (paper, strings, electric wire, various sheet-type materials, and tapes) and play indispensable roles in tension control systems. They are also suitable to use for cushioned start, power absorption, or as overload safety device (torque limiter).

1. Easy wide-range torque control

Transmission torque control over a wide range can be achieved easily, for transmission torque changes in proportion to the exciting current.

2. Usable under continuous slip conditions

With the use of powder to transmit torque, continuous slip on the operating surface is possible, and since transmission torque is independent of slip rotation speed, torque transmission performance is always stable.

3. Stable torque transmission

With an ideal operating surface and labyrinth shape, torque stability is maintained, even when the current is repetitively cycled ON/OFF.

4. Large heat capacity

Weizheng's brakes and clutches use highly heat-tolerant powder and have an ideal cooling structure that can be used under extremely demanding continuous slip conditions.

5. Smooth engagement and driving

Coefficients of static and dynamic frictions are nearly equal, which eliminate shocks during complete engagement and allows load-proportionate acceleration/deceleration.

Basic structure and operation

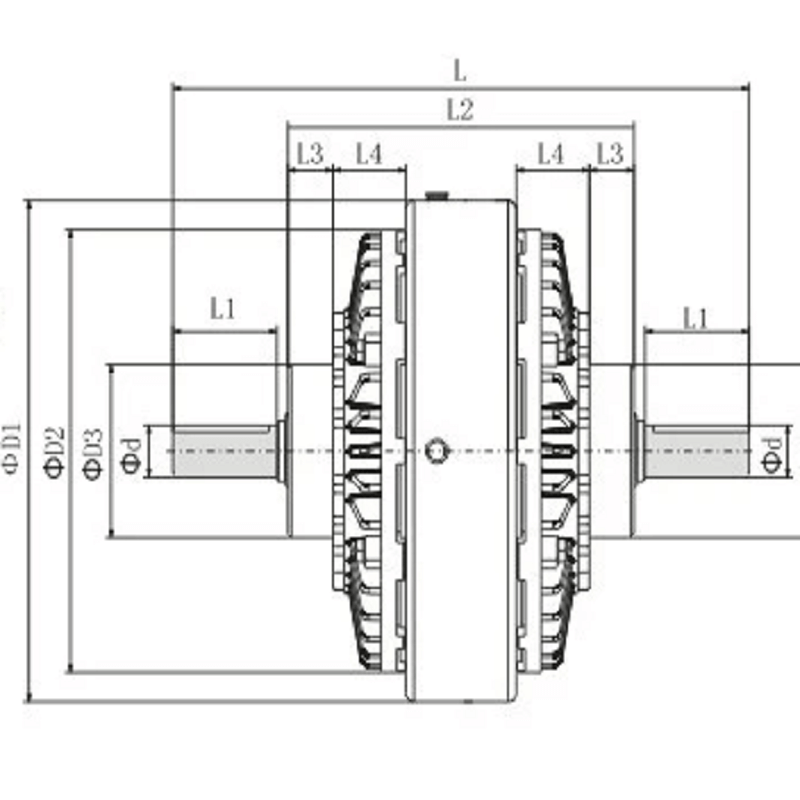

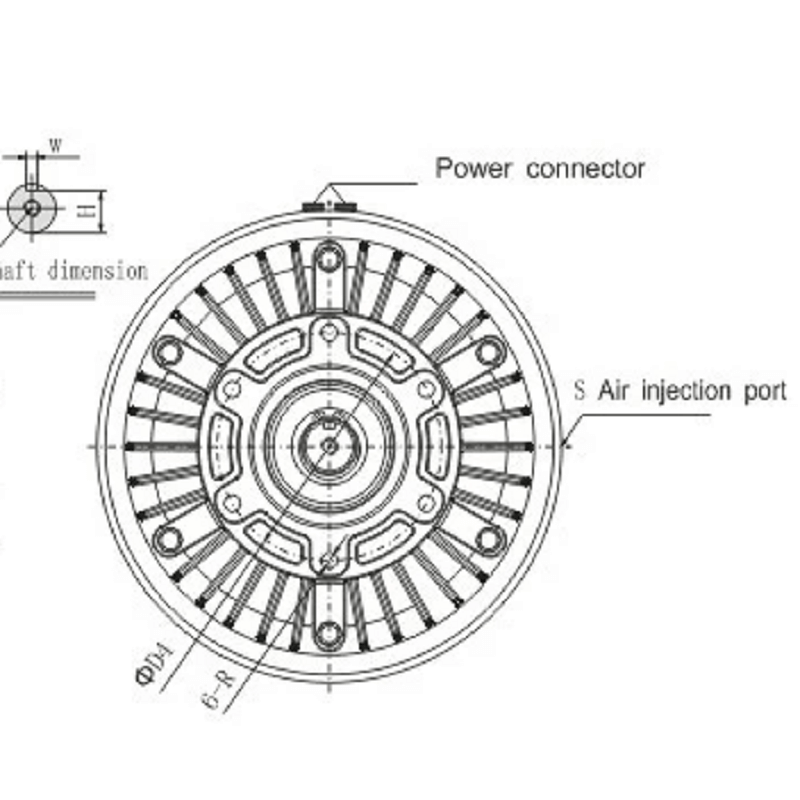

The right figure shows the basic structure of the powder clutch. The powder clutch consists of two concentric, cylindrical parts-a driving member (input side) and a driven member (output side)-that are assembled together in such a way so that there is a narrow gap called a "powder gap" between them. These members are supported by bearings so that they can rotate freely.

This gap is filled with a highly magnetic permeable powder (magnetic metal powder), where an exciting coil is positioned on the outer peripheral to supply an exciting current to the powder.

When the coil is not excited and the driving member is rotating, the powder becomes pressed against the operating surface of the driving member by the centrifugal force, and the driving member and the driven member remain disengaged.

When the coil is excited, magnetic flux passes through the powder and the powder becomes attracted between the pole faces in chainlike clusters. Torque is, then, transmitted by the linking power between the powder particles and by the friction between the powder and the operating surface.

Therefore, the powder clutch can be thought of as a friction clutch that uses magnetic metal powder as a torque transmission medium. When the driven member (output side) is fixed, it becomes the powder brake.

Without excitation

When the coil is not excited, the clutch becomes disengaged and torque is not transmitted. During this time, the powder is pressed against the outer peripheral of the powder gap by the centrifugal force.

With excitation

When the coil is excited, the powder becomes chained together inside the powder gap due to magnetic flux and torque is transmitted.

Ningxia Machinery Research Institute Co., Ltd. is registered in Yinchuan High-tech Development Zone. The manufacturing base is located in Jinfeng Industrial Park, Yinchuan City. It is mainly engaged in the research, development, production and sales of new electromechanical instruments, new materials and industrial automation control. The company was transformed from a provincial scientific research institute into an enterprise in June 2000. It was officially registered as Ningxia Machinery Research Institute (Limited Liability Company) in September 2002, and changed into Ningxia Machinery Research Institute Co., Ltd. in April 2014. The company covers an area of 123 acres, with a registered capital of 18.195897 million yuan and total assets of 153 million yuan. It is a technology-based joint-stock enterprise.

The company is a national high-tech enterprise, a national innovative pilot enterprise, a national intellectual property advantage enterprise, a Ningxia intellectual property demonstration enterprise, an autonomous region "specialized and special" demonstration enterprise, and a small giant enterprise in Yinchuan. The company has the national "Molding Quenching Technology and Equipment National Local Engineering Laboratory" and "Ningxia Equipment Manufacturing Technology Service and Quality Inspection and Testing Service Platform", has obtained CMA and CNAS qualifications, and can issue inspection and testing reports to the society; Ningxia Molded Quenching Machine Tool Engineering Technology Research Center" and "Enterprise Technology Center". Passed ISO9001-2000 quality system certification in 2003, CNAS National Laboratory certification in 2014, and National Quality/Environment/Occupational Health and Safety Management System certification in 2017.

The company has always been committed to the development of high-tech products, and its research and development activities are very active. There are more than ten new R&D projects each year, and the R&D results are fruitful. The company has obtained 51 national authorized patents, including 13 invention patents; registered 34 computer software copyrights, won 1 Chinese Patent Award Excellence Award, presided over the formulation of 1 national industry standard, and participated in the formulation of 2 national industry standards.