In recent years, environmental protection and sports are prevailing, and the utilization rate of bicycles has also been greatly improved. In order to increase the comfort and life of bicycles, general bicycles are equipped with shock absorbent devices to adapt to different road changes and provide shock absorbent functions to reduce bicycle damage. Magnesium alloy products have become the main accessories of bicycle shock absorbent fork due to their incomparable advantages such as low density, high strength and stiffness, good impact resistance and vibration damping, easy shaping and processing, beautiful surface, durability, low cost, easy recovery and meeting environmental protection requirements.

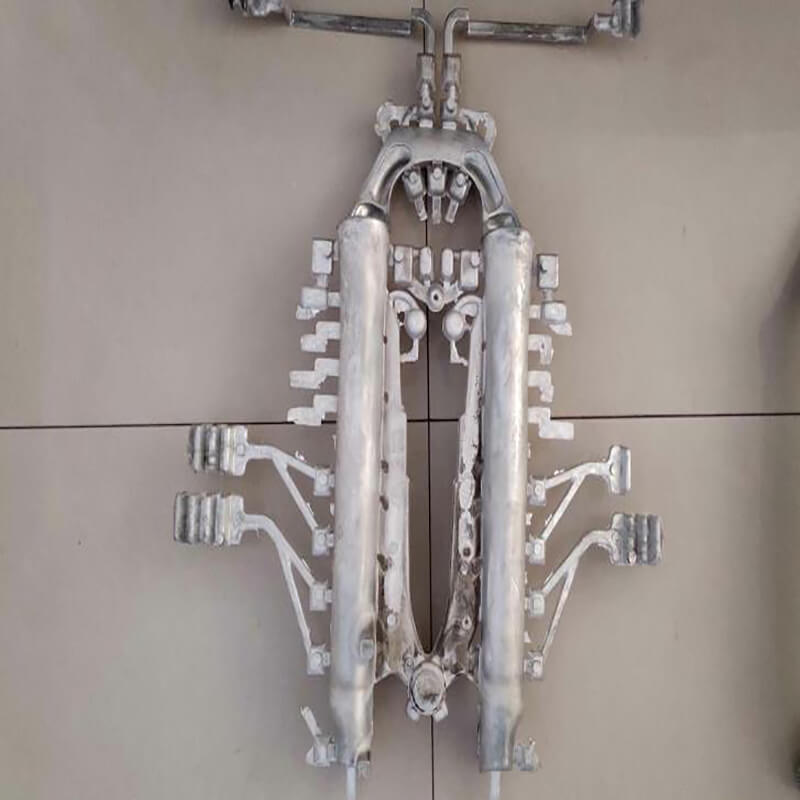

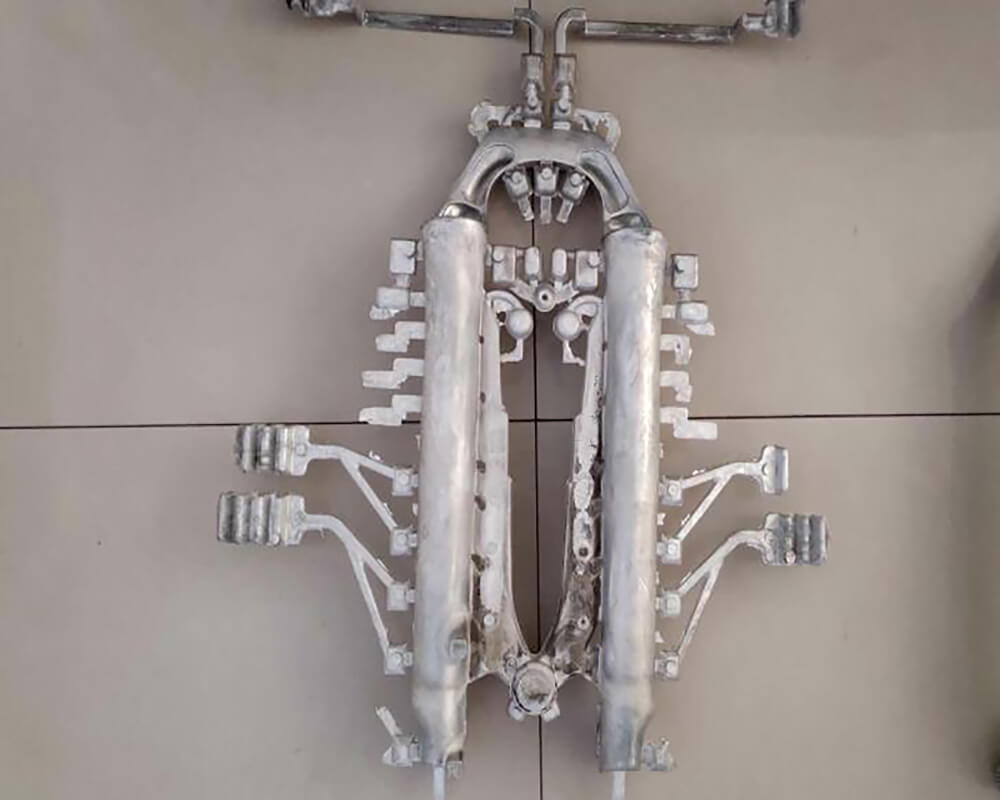

Name: Front fork

Application: 26/27.5/29 inch mountain bike

Material: aluminum alloy + magnesium alloy

Specifications: 9mm quick release version, 286 straight tube and 398 conical tube

Stroke: 100mm (large stroke can be customized)

Selling point: This product is air pressure shock absorber, commonly known as air fork, light weight, comfortable rebound

Weight: 26 inches about 16809 specifications with different weights between 1680g17809

Ningxia Zhongtai Magnesium Technology Co., Ltd. (referred to as Zhongtai Magnesium Industry) was established in 2018 with a registered capital of 200 million yuan. Committed to building a comprehensive magnesium alloy industrial base, including magnesium alloy production equipment base, national magnesium alloy research institute, international magnesium alloy product futures trading center, for rail transportation industry, automobile industry, military industry, 3C electronics industry, robot industry Lightweight provides technical support and industrialization guarantee.

main production:

Lightweight magnesium alloy parts such as magnesium alloy sheet and strip, rail transportation parts, auto parts, electric bicycle parts, military product parts, 3C product parts, etc. The company is located in Liupanshan Road, Yinchuan Economic Development Zone, covering an area of 67000m. It is a high-tech enterprise integrating R&D, production and sales of magnesium alloys. Currently, it is an accessory supplier for FAW, CRRC, Dongfeng and several electric bicycle manufacturers. Our company has established an in-depth strategic cooperation relationship with Jilin University, and has a magnesium alloy belt warm rolling production line, magnesium alloy semi-solid molding production line, magnesium alloy gravity casting production line, magnesium alloy extrusion molding production line, with structural design, CAE analysis products R & D capabilities, also has a variety of product testing equipment such as material spectrum analyzer, metal structure metallographic analyzer, three-coordinate detector, salt spray detection, mechanical detection and so on.

Warm rolling production line, magnesium alloy semi-solid forming production line, magnesium alloy gravity casting production line, magnesium

Alloy extrusion molding production line, with product design capabilities for structural design and CAE analysis,At the same time, it has amaterial spectrum analyzer, metal structure metallographic analyzer, three-coordinate detector, saltVarious product testing equipment such as fog testing, mechanical testing, etc.