Product Description

Inoculant

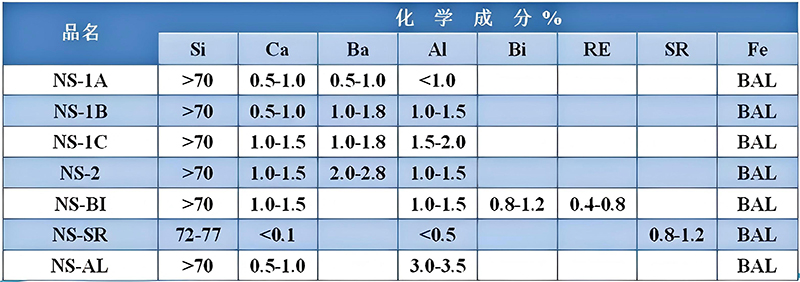

Silicon-Barium inoculant

The silicon-barium inoculant should simultaneously contain an appropriate amount of calcium (wCa = 1.0%~3.0%, wCa = 5.0%~7.0%, etc.) and aluminum (wAl = 1.0%~2.0%). As the barium content increases, the calcium content should also be appropriately increased to enhance the inoculating effect. Furthermore, the coexistence of barium with a certain amount of calcium helps reduce the chilling tendency.

In gray cast iron, silicon-barium inoculant, compared to other inoculants, more readily promotes the formation of uniform and fine Type A graphite. It shows a very low tendency to form Type D and Type E dendritic graphite; even in thin-walled castings with sections of 3-5mm, D+E type graphite does not appear. It significantly increases the eutectic cell count and improves the strength of gray cast iron. The level of barium content greatly influences the strength of gray iron, with medium-barium and high-barium grades being suitable for heavy-section gray iron castings.

In ductile cast iron, it can increase the nodule count, improve the nodularity of graphite, and eliminate cementite. Low-barium inoculants are primarily used in ductile cast iron.

It is used as a deoxidizer in steelmaking and as an inoculant in the foundry industry.

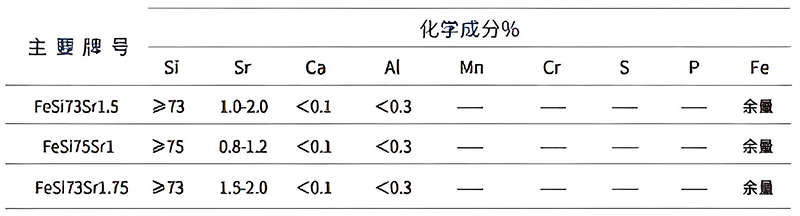

Silicon-Strontium inoculant

Strontium in silicon-strontium inoculant possesses strong inoculation effects. It offers advantages such as reducing chill, decreasing shrinkage porosity, improving cross-section uniformity, and generating minimal dross during treatment.

The typical composition of this inoculant is: Si ≥ 71%, Sr = 0.6%–1.2%, Ca ≤ 0.1%, Al ≤ 0.5%. Higher silicon content typically results in better and more stable inoculation effects. The requirements for calcium and aluminum content are lower but stricter compared to ferrosilicon and silicon-barium inoculants. The primary reason is that elevated levels of calcium and aluminum inhibit the graphitization potential of strontium, rendering the strontium inoculation ineffective.

Silicon-strontium inoculant is primarily used for gray cast iron and ductile iron that does not contain Cerium (Ce). Its prominent feature in gray cast iron is that while reducing chill, it does not significantly increase the eutectic cell count, resulting in a lower tendency for shrinkage cavities and porosity. This helps prevent leakage, making it suitable for castings like cylinder blocks and heads with varying wall thicknesses and strict leak-tightness requirements.

Details Images

Packing & Delivery

Supplier Profile

Ningxia Yilong New Materials Technology Co., Ltd., established in September 2019 and located in the Lanshan Industrial Park, Hongguozi Town, Huinong District, Shizuishan City, Ningxia, is a technology-based enterprise specializing in the research and development, production, and international trade of casting alloy materials.The company's core business focuses on the processing, sales, and import and export of key casting additives, such as spheroidizers and inoculants. Its product line includes a wide range of spheroidizers, including rare earth magnesium-silicon series, to meet diverse smelting processes and casting performance requirements. These spheroidizers can crystallize graphite in molten cast iron into spheres, significantly improving the strength and toughness of ductile iron, serving a wide range of metallurgical casting applications. Leveraging core ferroalloy smelting technologies and a comprehensive quality control system, the company's products have earned international recognition for their stable performance. They are primarily exported to developed manufacturing countries such as South Korea and Japan, meeting local demand for high-end castings.

The company boasts comprehensive industry chain services. In addition to its core products, it also offers supporting services such as refractory material sales, foundry machinery manufacturing and sales, and foundry molding material sales. It also provides technology research and development, transfer, and consulting services for casting alloy materials. Leveraging its comprehensive advantages of "technology + products + services," as well as its qualifications for import and export of goods and technology, the company continues to deepen its collaboration with overseas clients, establishing a professional and reliable brand image in the global foundry materials market.

Moving forward, the company will continue to leverage its domestic resource advantages while focusing on international market demand. With differentiated products and precise services, it aims to contribute to the upgrading of the global manufacturing industry and consolidate its competitiveness in Japan, South Korea, and overseas markets.