Product Description

Nodularizer

The additive that causes the graphite in cast iron to crystallize into a spherical form is called a "nodularizer." The main components of a "nodularizer" are nodulizing elements, such as Mg, Ce, Ca, etc. The spherical graphite in ductile iron is formed after the molten iron is treated with a nodularizer, which significantly increases its strength compared to gray cast iron and provides better toughness than malleable cast iron, while still retaining a series of advantages of gray cast iron.

In China, the commonly used nodularizer is ferrosilicon rare earth magnesium alloy, while most foreign countries use magnesium-based nodularizer (pure magnesium and magnesium alloys), and a few countries use calcium-based nodularizer.

The basic requirements for a nodularizer are:

1. Strong nodularizer capability;

2. Abundant resources, low cost, and ease of melting;

3. Strong adaptability to molten iron with various compositions (such as degree of eutecticity, sulfur content, anti-nodularizer elements, and alloying elements) and temperatures;

4. Good kinetics for nodularizer reactions, relatively stable reactions, easy removal of reaction products, low usage, minimal temperature drop, and good nodularizer treatment processability.

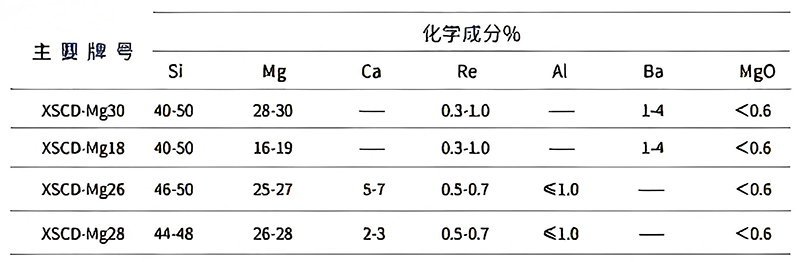

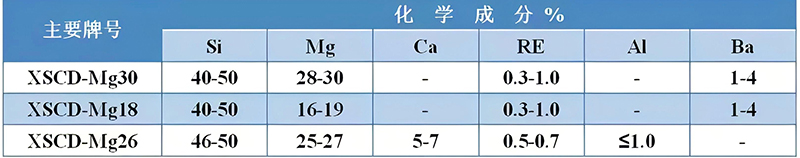

Silicon-Magnesium Alloy

Silicon-magnesium alloy is a alloy smelted from ferrosilicon, magnesium, and trace amounts of silicon-calcium and rare earth elements. It is a high-performance nodulizer with strong deoxidizing and desulfurizing capabilities, as well as an excellent nodulizing effect. It is commonly known as the "High-Mg Nodulizer".

Purpose

Primarily used as the core material for cored wire used in nodularizing treatment.

· Other Grades: Can be customized according to customer requirements.

· Particle Size: 0-2mm, 0-2.5mm, 1-3mm. Custom sizing available upon request.

· Packaging & Storage/Transport: Packaging, storage, and transportation can be arranged as per customer requirements. Must be kept dry to prevent moisture absorption

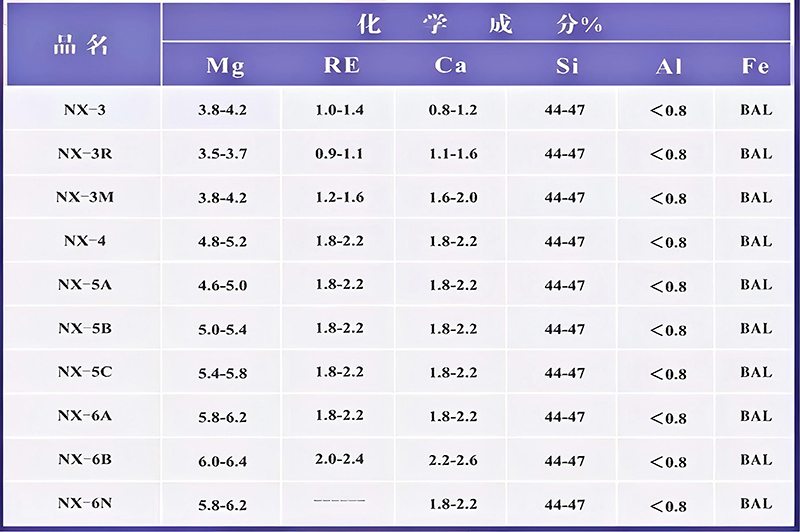

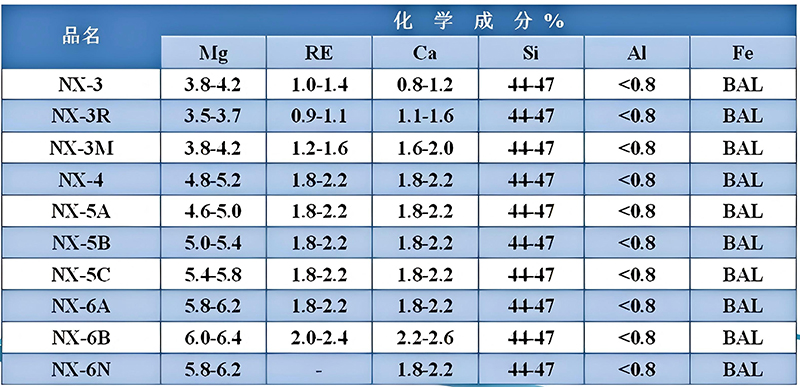

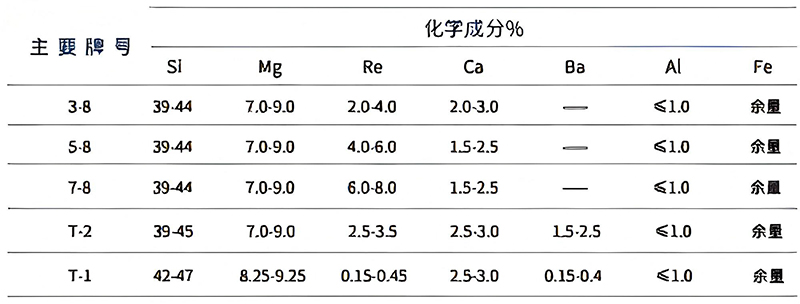

Rare earth magnesium ferrosilicon alloy

Details Images

Packing & Delivery

Supplier Profile

Ningxia Yilong New Materials Technology Co., Ltd., established in September 2019 and located in the Lanshan Industrial Park, Hongguozi Town, Huinong District, Shizuishan City, Ningxia, is a technology-based enterprise specializing in the research and development, production, and international trade of casting alloy materials.The company's core business focuses on the processing, sales, and import and export of key casting additives, such as spheroidizers and inoculants. Its product line includes a wide range of spheroidizers, including rare earth magnesium-silicon series, to meet diverse smelting processes and casting performance requirements. These spheroidizers can crystallize graphite in molten cast iron into spheres, significantly improving the strength and toughness of ductile iron, serving a wide range of metallurgical casting applications. Leveraging core ferroalloy smelting technologies and a comprehensive quality control system, the company's products have earned international recognition for their stable performance. They are primarily exported to developed manufacturing countries such as South Korea and Japan, meeting local demand for high-end castings.

The company boasts comprehensive industry chain services. In addition to its core products, it also offers supporting services such as refractory material sales, foundry machinery manufacturing and sales, and foundry molding material sales. It also provides technology research and development, transfer, and consulting services for casting alloy materials. Leveraging its comprehensive advantages of "technology + products + services," as well as its qualifications for import and export of goods and technology, the company continues to deepen its collaboration with overseas clients, establishing a professional and reliable brand image in the global foundry materials market.

Moving forward, the company will continue to leverage its domestic resource advantages while focusing on international market demand. With differentiated products and precise services, it aims to contribute to the upgrading of the global manufacturing industry and consolidate its competitiveness in Japan, South Korea, and overseas markets.