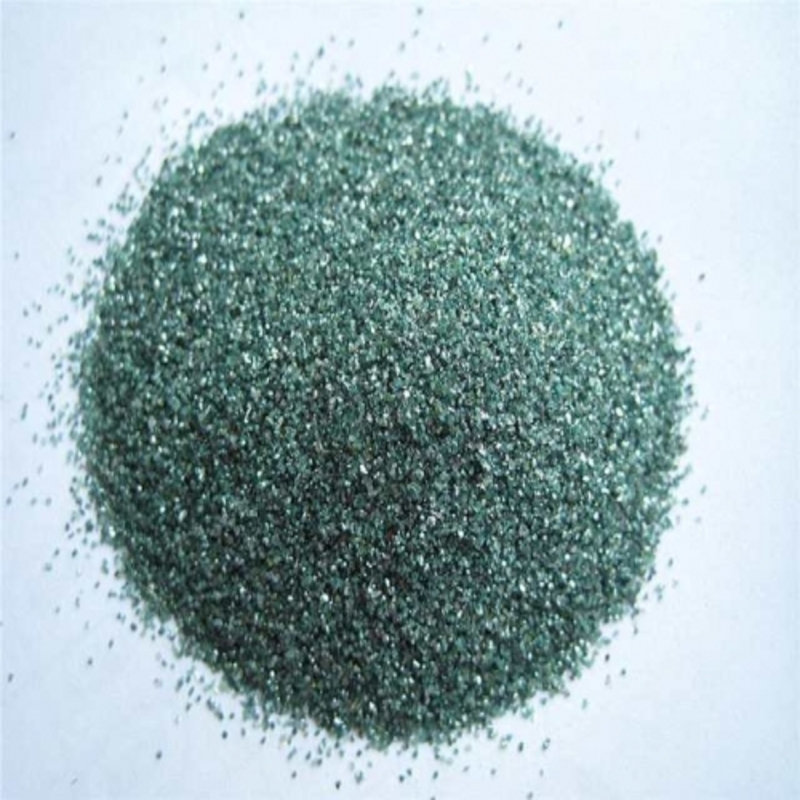

The green silicon carbide powder is a kind of product that deep processes the green silicon carbide raw block through superfine grinding. The main equipment is: bamak crushing, Raymond grinding or ball mill pulverizing. Then we can use ultrasonic and screen out the mesh number that we use; silicon carbide powder is formed. There are various specifications of w63-w1.5. Green silicon carbide powder W is mainly used for coating, coating, sealing parts, etc.

Green silicon carbide micro green silicon carbide micro powder is used more and more widely. The commodity is mainly used for the production of refractory materials, foam ceramic occupation, solar silicon wafer cutting, crystal cutting and grinding, car originating production, special paint occupation, plastic products modification, desulfurization power supply and environmental protection occupation. At present, the main companies in China adopt the combination of dry, wet, dry and wet methods. Produce silicon carbide powder to meet different needs of different products.

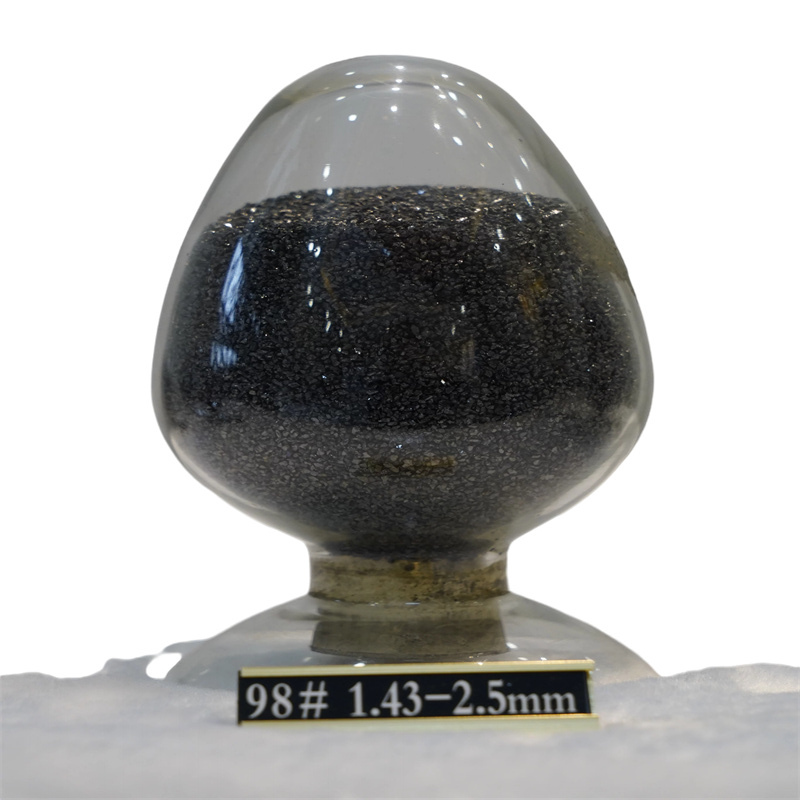

The green silicon carbide powder is classified as follows according to Chinese and European specifications:

Chinese specifications: W63, W50, W40, W28, W20, W14, W10, W7, W5, w3.5, w2.5, w1.5.

Eurocodes: f280, F320, F400, f500, F600, F800, F1000, f1200, f1500, f1800.

| Specification of Green Silicon Carbide | |||

| Size | SIC | Fe2O3 | F.C. |

| F230 -F1200, JIS #240-#8000, or any other sizes by customer's requirement. | 99% Min | 0.2% Max | 0.2% Max |

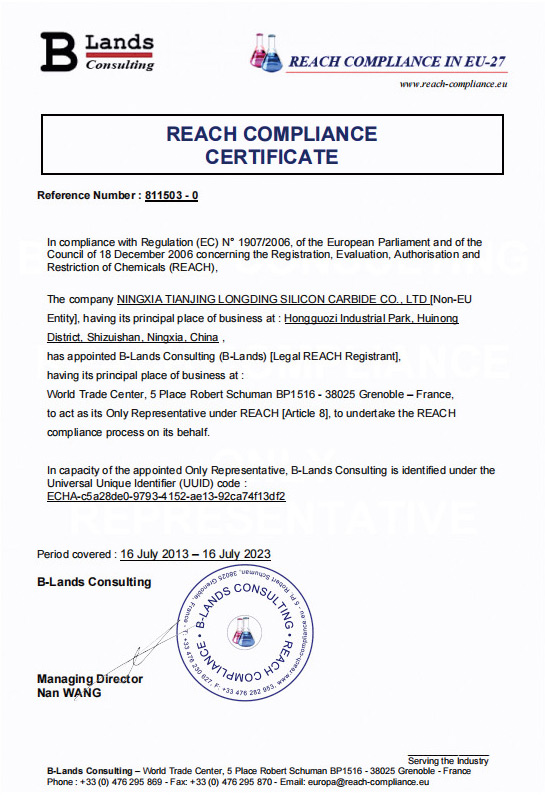

At present, our company has passed the "REACH" certification, and can export high-quality silicon carbide with stable quality. | |

Quality control

Vingxia Tianjing Longding Silicon Carbide Co, Ltd. has established a modern quality testing center andis equipped with advanced testing equipment at home and abroad. The company strictly implements theSO9001 quality management system, from raw material entry, smelting, grading, processing to finishedproduct delivery, and the entire process quality tracking and monitoring, fully ensuring the productquality requirements required by customers.

Using domestic and foreign advanced silicon carbide processing and production equipment and cleaningmagnetic separation, shaping, screening process, independent optimization of process line configuration.with low production cost, stable product quality, in line with GB, JIS, FEPA, DIN and other differentstandards, greatly improve the market competitiveness of products.

The company's quality inspection center is equippedwith professional testing personnel, in addition toroutine testing items, it can also test special indica-tors such as S, P, Ti, AI,O,, CaO, MgO, etc. It is aresearch and development and innovation capabili-ties of the testing center.

The company uses silicon carbide smelted from anthracite, which has high SiC content, stablephysical and chemical indicators, and high crystallization density. High quality and dense siliconcarbide products have a content of up to 99.00%, a specific gravity greater than 3,20, and a bulkdensity greater than 1.65g/cm3.

Packing & Delivery

Company Profile

Ningxia Tianjing Longding Silicon Carbide Co., Ltd., founded in 1997, mainly produces silicon carbide and its products for further processing. The company is located in Dingsheng Road, Hongguozi Park, Shizuishan Economic and Technological Development Zone, adjacent to National Highway 110, covering an area of more than 300 mu, with a registered capital of 46.875 million yuan. The company has more than 240 employees and more than 20 technical research and development personnel. The company has obtained 18 utility model patents and 1 software copyright certificate.

The company has two substations, including one 220KVA substation with a capacity of 120000KVA and one 110KVA substation with a capacity of 50000KVA; The total capacity of the plant is 170000KVA.

The company started from the 3000KVA smelting furnace in 1997, worked hard and continued to innovate. For the silicon carbide smelting furnace, the company has continued to reform and innovate. Up to now, the company has two 40000 KVA silicon carbide smelting furnace production lines, with a design production capacity of 85000 tons/year. This production line adopts a number of proprietary technologies and advanced smelting process equipment. It has the advantages of high automation, low process unit consumption, and excellent product quality.

Relying on high-quality raw materials and advanced technology, the products produced by the company have outstanding quality advantages. The content of high-quality and dense silicon carbide products is more than 98%, the proportion is more than 3.2g/cm3, and the bulk density is more than 1.65g/cm3. The products have high toughness, high strength, and high purity physical and chemical properties. The products are widely used in abrasives, steel, refractories, solar photovoltaic, semiconductor, military aerospace, building materials grinding wheels, ceramics and other industries, with strong market competitiveness.

Since its establishment, the company has adhered to the entrepreneurial concept of "building a business with integrity and keeping quality eternal", and has been constantly pioneering in the market. It has been awarded various honorary titles such as advanced enterprise, honest operation enterprise, advanced unit of quality management, and advanced unit of energy conservation by higher authorities and local governments for many times. Its products have been recognized as "Ningxia Famous Brand Products".

At present, the company has been authorized with "REACH" certificate and has the ability to export silicon carbide independently.

In the face of the increasingly competitive market, our company will vigorously carry forward the enterprise spirit of "striving to surpass and pursue excellence", actively practice the core values of "integrity, responsibility, innovation and dedication", strive to pursue customer satisfaction, constantly keep abreast of higher standards, move towards higher goals, and wholeheartedly work with people from all walks of life to create a better tomorrow!

Introduction to equipment and facilities

Relying on the smelting production line, the company vigorously develops the deep processing industry chain. We can produce the first, second and third stage sand, grain size sand and fine powder of different specifications and models according to customer requirements.

Five micro powder (Raymond Mill) production and processing lines, with a processing capacity of 30000 tons/year; Four pneumatic mill production lines with processing capacity of 15000 tons/year; Two screening (Bamak) production lines with a processing capacity of 50000 tons/year.

It adopts domestic advanced silicon carbide processing and production equipment, blowing, magnetic separation, shaping and screening processes, and independently optimizes the process line configuration. It has low production cost, stable product quality, and meets the requirements of GB, JIS, FEPA, DIN and other different standards, greatly improving the market competitiveness of products.