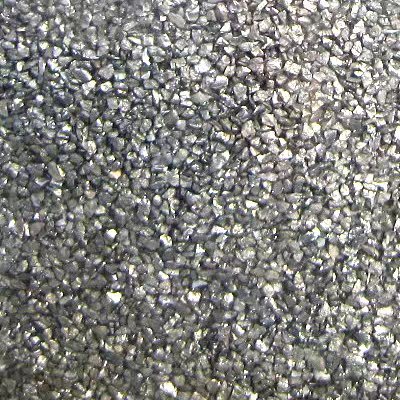

It is a highly reactive, amorphous SiO 2 spherical particle with a particle size 1/100 of that of cement particles, which can fill in between cement particles and also react with hydration products to produce gels, as well as with materials with alkaline substances to produce gels.

Application of silica fume in concrete: modification mechanism and function of silica fume After mixing into cement concrete, it can fill in the cement particle gap well and make the paste more dense. In addition, it combines with free Ca(OH)2 to form a stable calcium silicate hydrate 2CaO ?SiO 2?nH2 O, which has a higher gel strength than Ca(OH)2 crystals.

Since 2003, Silica Materials Ltd. has been designing and building equipment for the collection and densification of microsilica and distributing it.

the collected and densified equipment and distribute the collected microsilica in the domestic market.

The collected microsilica is sold in the domestic market.

Silica Materials has a ferrosilicon plant that produces approximately 2,000 tons per month of G85

Producing approximately 2,000 tons of G85 per month

Silicon Materials also works with one of the largest ferrosilicon plants

contracted to design, build and maintain the collection and concentration

equipment. We have the exclusive right to distribute the micro-silica collected by our own equipment.

Exclusive distribution of the microsilica collected by our own equipment has a capacity of 5,000 tons of G85 per month.

Therefore, our total supply capacity is approximately 7,000 tons per month.