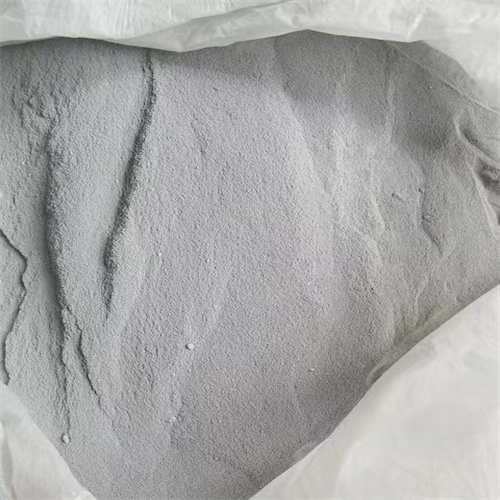

Micro-silica powder, also called silica ash or cohesive silica ash, is produced by ferroalloys in smelting ferrosilicon and industrial silicon (silicon metal), and a large amount of highly volatile SiO2 and Si gas is produced in the mineral-heated electric furnace, which is precipitated by rapid oxidation and condensation with air after the gas is discharged. It is a by-product of large industrial smelting, and the whole process needs to be recovered with dust removal and environmental protection equipment, and because of the small density, it also needs to be encrypted with encryption equipment.

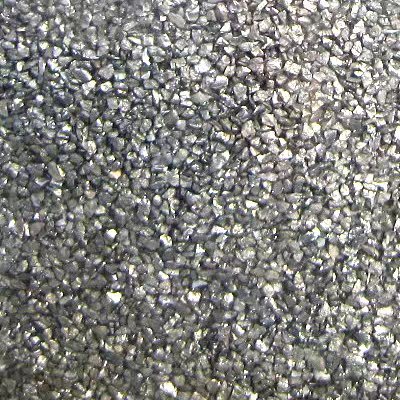

In terms of particle size, silica micronized powder processed from natural quartz has a relatively large particle size of 200 mesh, 300 mesh, 400 mesh, 500 mesh, 600 mesh, 800 mesh, 1000 mesh, 1250 mesh, 3000 mesh, 5000 mesh, 10000 mesh, etc. It is a powder state. The fineness of micro-silica powder is less than 1μm accounting for more than 80%, the average particle size in 0.1-0.3μm, is a kind of gray state.

Since 2003, Silica Materials Ltd. has been designing and building equipment for the collection and densification of microsilica and distributing it.

the collected and densified equipment and distribute the collected microsilica in the domestic market.

The collected microsilica is sold in the domestic market.

Silica Materials has a ferrosilicon plant that produces approximately 2,000 tons per month of G85

Producing approximately 2,000 tons of G85 per month

Silicon Materials also works with one of the largest ferrosilicon plants

contracted to design, build and maintain the collection and concentration

equipment. We have the exclusive right to distribute the micro-silica collected by our own equipment.

Exclusive distribution of the microsilica collected by our own equipment has a capacity of 5,000 tons of G85 per month.

Therefore, our total supply capacity is approximately 7,000 tons per month.