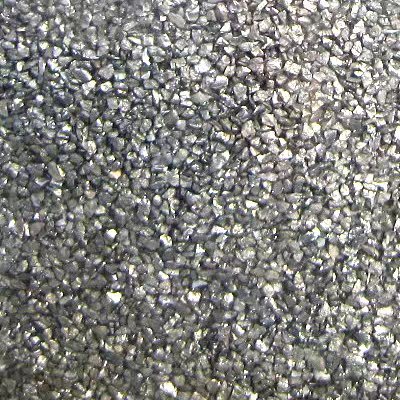

Carbon enhancer used in casting, can significantly increase the amount of scrap steel, reduce the amount of pig iron or do not use pig iron. Electric furnace melting feeding method, carbon enhancer should be put in with the scrap and other furnace materials, small doses of additions can be chosen to add to the surface of the molten iron. But to avoid large quantities to the molten iron feeding, in order to prevent excessive oxidation and carbon increase effect is not obvious and the castings carbon content is not enough. The amount of carbon additive added is determined according to the ratio of other raw materials and carbon content. Different kinds of cast iron, according to the need to choose different types of carbon enhancer. The characteristics of the carbon enhancer itself choose pure carbon graphitized material, reduce the excess impurities in pig iron, carbon enhancer selection can reduce the production cost of castings.

Since 2003, Silica Materials Ltd. has been designing and building equipment for the collection and densification of microsilica and distributing it.

the collected and densified equipment and distribute the collected microsilica in the domestic market.

The collected microsilica is sold in the domestic market.

Silica Materials has a ferrosilicon plant that produces approximately 2,000 tons per month of G85

Producing approximately 2,000 tons of G85 per month

Silicon Materials also works with one of the largest ferrosilicon plants

contracted to design, build and maintain the collection and concentration

equipment. We have the exclusive right to distribute the micro-silica collected by our own equipment.

Exclusive distribution of the microsilica collected by our own equipment has a capacity of 5,000 tons of G85 per month.

Therefore, our total supply capacity is approximately 7,000 tons per month.