Product Description

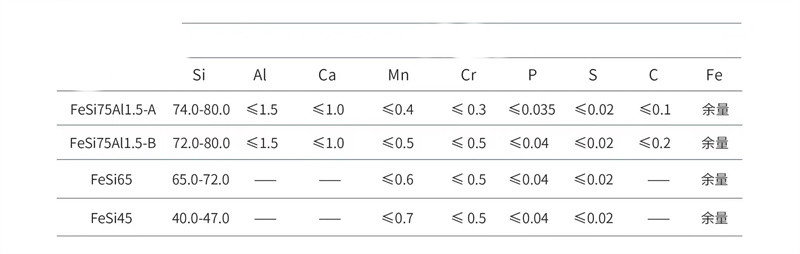

Ferrosilicon

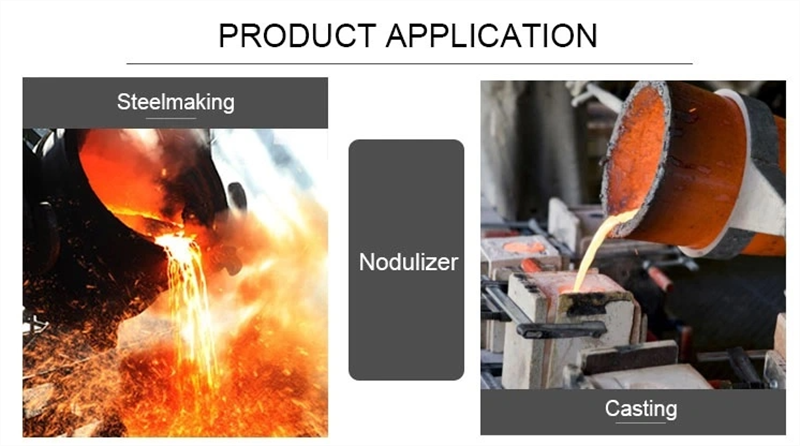

It is mainly used for deoxidation and denitrification in steelmaking, and also as Si element additive to improve the strength of steel; adding cast iron can be used as a cast iron inoculant to improve the performance of cast iron.

Other grades: can be customized according to user requirements;

Granularity: can be processed according to user requirements;

Packing: plastic woven ton bags, which can be packed, stored and transported according to the requirements of the buyer to prevent moisture.

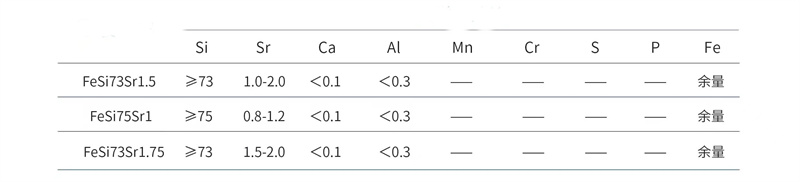

Silicon strontium inoculant

Silicon strontium inoculant The strontium in the silicon strontium inoculant has a strong inoculation effect, which has the advantages of eliminating white mouth, reducing shrinkage, improving cross-section uniformity, and reducing the amount of scum during processing. The typical components of the inoculant are: wS>71%, wSr=0.6%~12%, wCa<01%, WAl<0.5%. Silicon strontium inoculant

The incubation effect is good and stable, and the content of calcium and aluminum is lower but stricter than that of ferrosilicon and silicon-barium. Silicon strontium inoculant is mainly used for gray cast iron and ductile iron without Ce. Among gray cast iron, its outstanding feature is that while eliminating white mouth, the eutectic group does not increase much, and the tendency of shrinkage and shrinkage is small, which can prevent Leakage, suitable for cylinder block and cylinder head castings with uneven wall thickness and leakage requirements.

Other grades: can be customized according to user requirements;

Granularity: can be processed according to user requirements;

Packing: plastic woven ton bags, which can be packed, stored and transported according to the requirements of the buyer to prevent moisture.

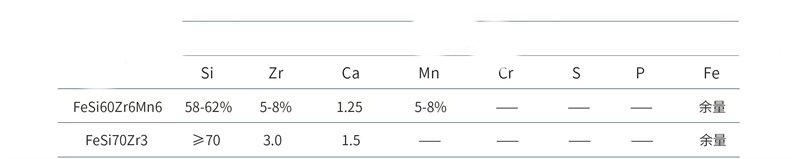

Silicon zirconium inoculant

The wZr in the silicon-zirconium inoculant is generally 3% to 6%, which has strong anti-pregnancy recession ability, reduces the tendency of white mouth, improves the graphite structure, and obtains fine and uniform A-type graphite. At the same time, zirconium has high deoxidation, desulfurization and nitrogen fixation ability, which is beneficial to eliminate nitrogen holes in castings.

Other grades: can be customized according to user requirements;

Granularity: can be processed according to user requirements;

Packing: plastic woven ton bags, which can be packed, stored and transported according to the requirements of the buyer to prevent moisture.

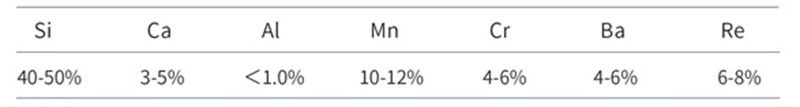

Rare earth calcium barium

Other grades: can be customized according to user requirements;

Granularity: can be processed according to user requirements;

Packing: plastic woven ton bags, which can be packed, stored and transported according to the requirements of the buyer to prevent moisture.

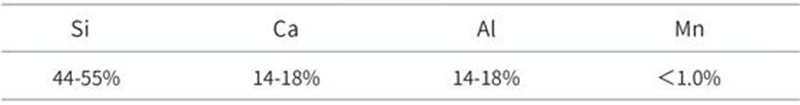

Silicon calcium manganese

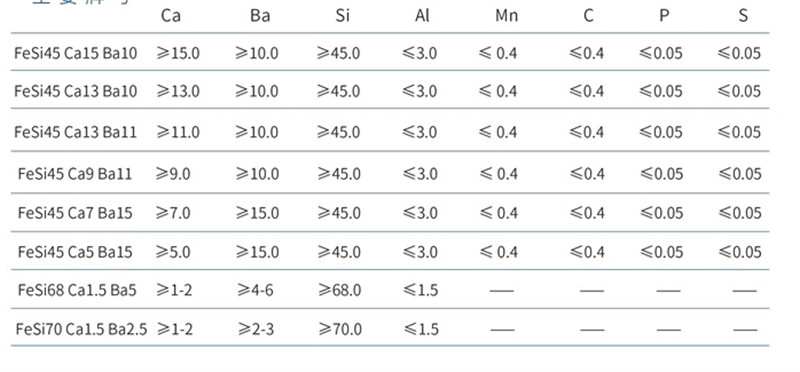

Silicon barium

The silicon-barium inoculant has a strong ability to eliminate white mouth and graphitization, and has a good anti-inoculation recession effect.

The role of chemical eutectic group is currently the most widely used in foundries at home and abroad.

Silicon barium inoculants can be divided into low barium wBa=1.0%~4.0%, medium barium wBa according to the content of barium.

=7.0%~10.0%, high barium wBa=12.0%~18.0%, with the increase of barium content, the anti-recession ability

gradually increase.

The silicon-barium inoculant should also contain an appropriate amount of calcium (wCa=1.0%~3.0%, wCa=5.0%~

7.0%, etc.) and aluminum (wAl=1.0%~2.0%), with the increase of barium content, the calcium content should also increase appropriately.

In order to strengthen the inoculation effect, at the same time, the coexistence of barium and a certain amount of calcium is beneficial to reduce the tendency of chilling.

Compared with other inoculants, silicon-barium inoculants are easier to obtain uniform and fine A-type graphite in gray cast iron.

D-type and E-type dendritic graphite have a small tendency to form, and D+ day will not appear even in thin-walled parts of 3~5mm.

Type graphite can strongly increase the number of eutectic groups and improve the strength of gray iron, and the level of barium content has a great influence on the strength of gray iron. Medium and high barium are suitable for thick and large gray iron castings. In ductile iron, the number of graphite nodules can be increased, the roundness of graphite can be improved, and cementite can be eliminated. In ductile iron, low-barium inoculants are mainly used.

Other grades: can be customized according to user requirements;

Granularity: can be processed according to user requirements;

Packing: plastic woven ton bags, which can be packed, stored and transported according to the requirements of the buyer to prevent moisture.

Rare Earth Inoculant

Rare earth inoculants include: rare earth silicon, rare earth silicon calcium, rare earth silicon calcium barium, etc. Rare has strong deoxygenation and deoxygenation

Sulfur ability, the generated sulfide easily serves as the substrate for graphite nucleation, and has the effect of non-spontaneous nucleation. rare earth pair

The graphitization of cast iron has a dual effect. When the rare earth content in the molten iron is less than the critical value, it can prevent white mouth and promote

Progressive graphitization, and when the content exceeds the critical value, due to its strong supercooling, there is a tendency to increase the white mouth. when joining

When the compound inoculant is composed of elements such as Ca, Al, Ba, etc., a more prominent inoculation effect can be obtained. Rare earth breeding

The main agent should be cerium, and lanthanum will increase the tendency of white mouth, so it must be limited.

Other grades: can be customized according to user requirements;

Granularity: can be processed according to user requirements;

Packing: plastic woven ton bags, which can be packed, stored and transported according to the requirements of the buyer to prevent moisture.

Details Images

Packing & Delivery

Ningxia Xinshuncheng is a metallurgical product company specializing in the research, development and production of special alloy materials such as nodularizing agent (core wire) and inoculant (core wire). The company is located in Binhe Industrial Park, Huinong District, Shizuishan City, Ningxia, facing the surging Yellow River in the east, backed by Helan Mountains, 3 kilometers away from Beijing-Tibet Expressway and 1 kilometers away from Baolan Railway. The location of the factory has all the raw material resources required for the production of special ferroalloy products such as cored wire, nodularizing agent, inoculant, etc., and has a unique geographical advantage in the collection and organization of raw and auxiliary materials.

The company can choose suitable materials for the company according to the type of castings produced by the foundry and product quality requirements. Such as: special spheroidizer and inoculant for castings with low temperature impact requirements for large-section cast wind power; special spheroidizer and inoculant for thin-walled castings; .

The company currently has five alloy production lines, using 1000Kg, 2000Kg and 3000Kg intermediate frequency electric furnace alloy melting complete systems, with advanced alloy cooling device, which greatly reduces the segregation and oxidation in the process of alloy production; The closed dust-free automatic assembly line; the spheroidizing line and the inoculating line adopt the modern core-spun wire unit, which realizes the quality control of the whole process of material entering the factory, process production, and finished product warehousing, and ensures the stability of product quality.

The company specializes in providing: nodularizing agent (wire), inoculant (wire), silicon calcium alloy, silicon strontium alloy, silicon zirconium alloy, rare earth inoculant, etc., and also provides inoculant block, vermicularizing agent, pretreatment agent, low silicon silicon Casting accessories such as iron.

The company has a strong technical team and focuses on the innovation of intellectual property rights. Technically, it currently has five invention patents and 29 utility model patents. Research and develop new materials and new processes to lead the market demand of the foundry industry. Application: Provide a full range of technical services and process solutions for foundry enterprises to solve difficult problems encountered in the production process. Our goal: to provide foundry enterprises with reliable products and comprehensive services of technical solutions. The company hopes to work hand in hand with more excellent foundry enterprises to create brilliant together!

Xinshuncheng Company--Because of the quality, it is trustworthy!