Product Description

Product Name: Black Silicon Carbide

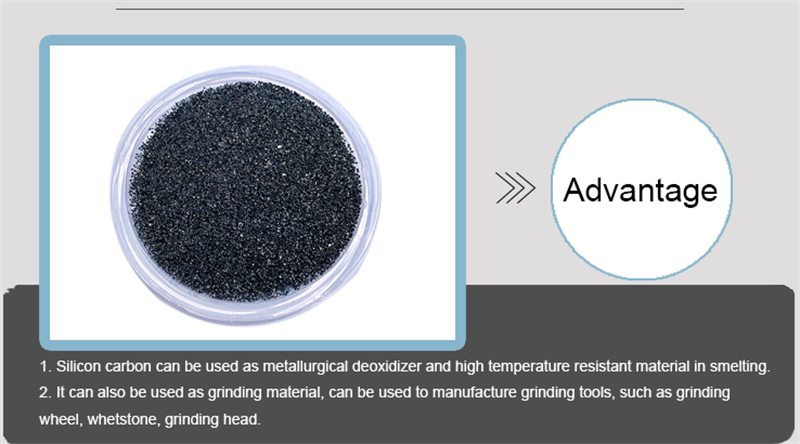

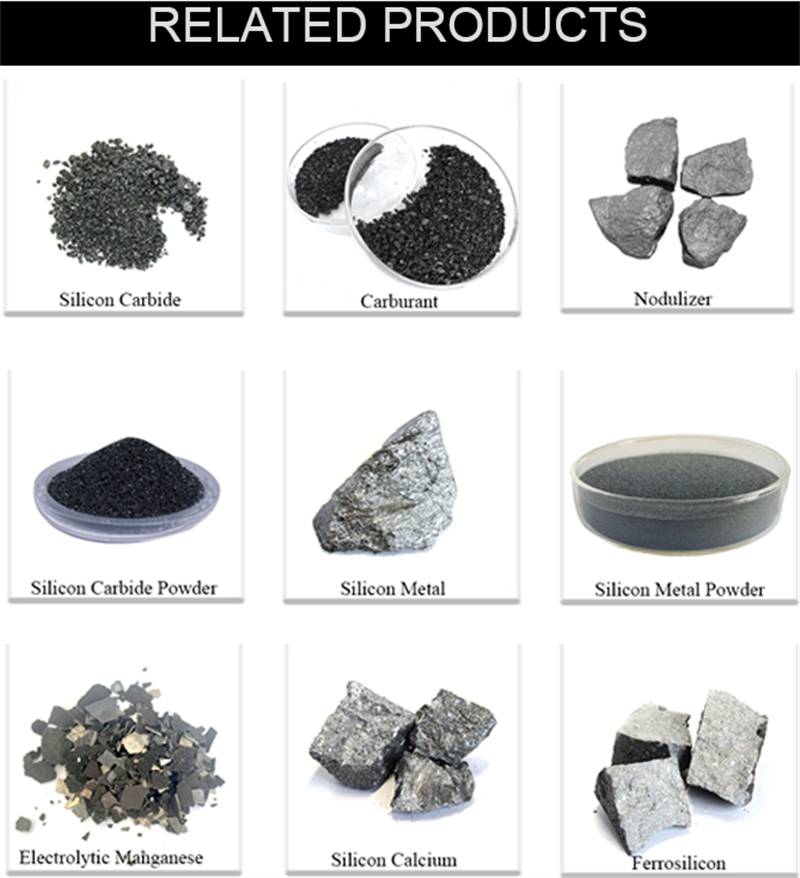

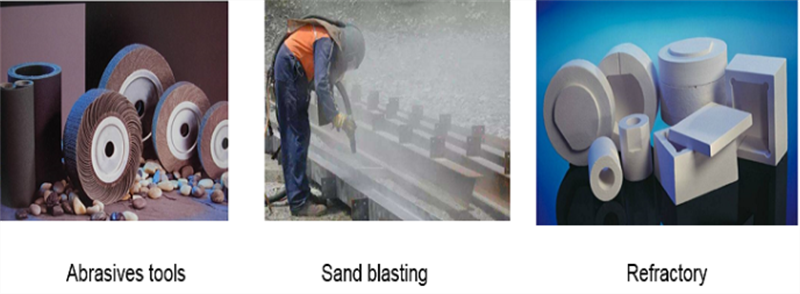

Black silicon carbide (SIC) is made from quartz sand and carbon( anthracite coal tar or petroleum coke) in electric esistance furnace at high temperature. It has the characteristic of high hardness, excellent electrical and heat conductivity, low thermal expansion, and high abrasion resistance. Thus, SIC is the most suitable material of abrasives, refractories, deoxidizer of metallurgical, special ceramics, electric heating elements and so on.

Silicon carbide SiC, also known as carborundum, is produced by melting a mixture of sillica sand and cokes in ultra high power electric furnaces.

Silicon carbide SiC is chemically stable and has high corrosion resistance, which makes it hard to corrode from exposure to alkali or acid. It is also characterized by its high hardness, outstanding heat resistance, low thermal expansion, resistance to chemical reaction, and ability to function as a semiconductor. Currently, Chinese industrial production of silicon carbide is divided into black SiC and green SiC, which mainly has four major application fields : functional ceramics, refractories, abrasives and metallurgical raw materials.Quick Details

- Warranty:

- 1 years

- Type:

- Abrasives

- Customized support:

- OEM, ODM

- Place of Origin:

- Ningxia,China

- Brand Name:

- Goal

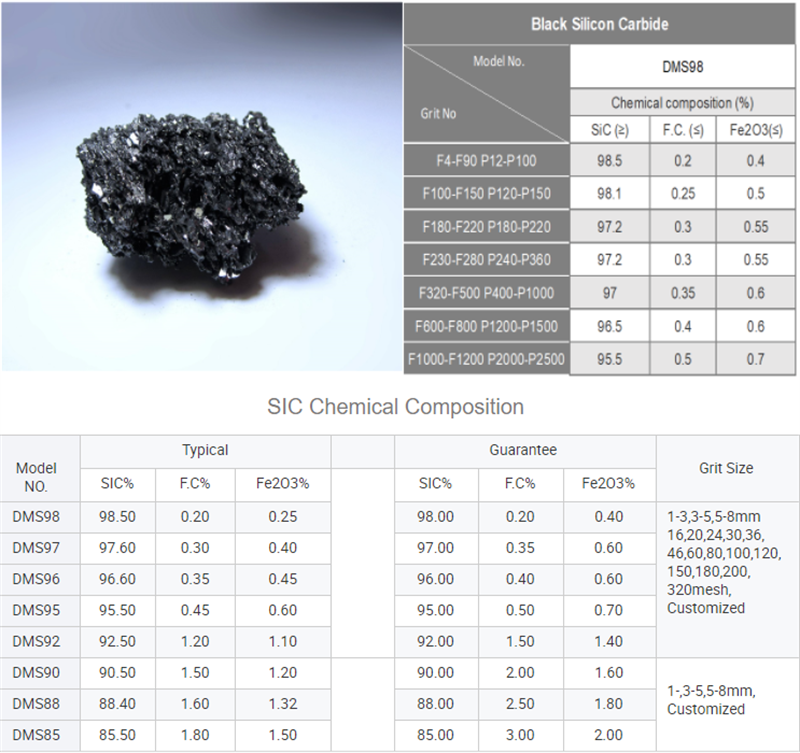

- Model Number:

- DMS98-08

- Usage:

- Polishing,grinding,sandblasting,metallurgical

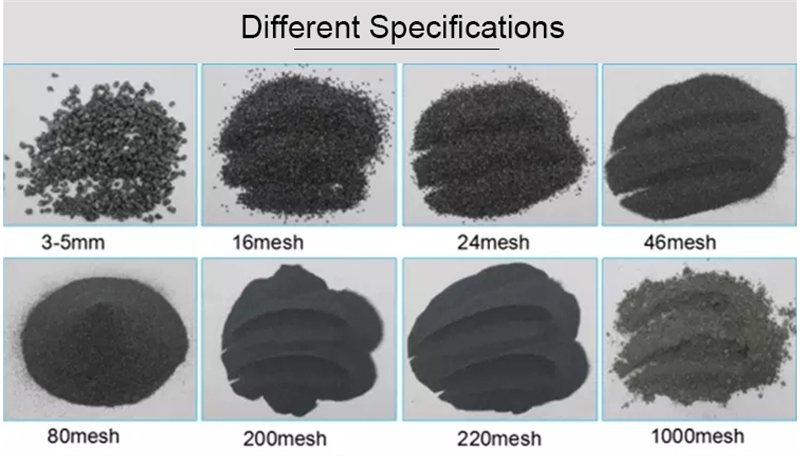

- Abrasive Grain Sizes:

- 0-1,1-3,3-5,0-10mm, F12-F220, customized

- Product name:

- Silicon carbide powder/SIC powder

- Standard:

- FEPA,JIS

- Other name:

- Carborundum, Emery

- Moh's hardness:

- 9.50

- Density:

- 3.45

- Color:

- Black

- Chemical Composition:

- SIC,Fe2O3

- Sample:

- Free

- MOQ:

- 33Tons

- Package:

- 25Kg/Bag,Jumbo Bag or Customized

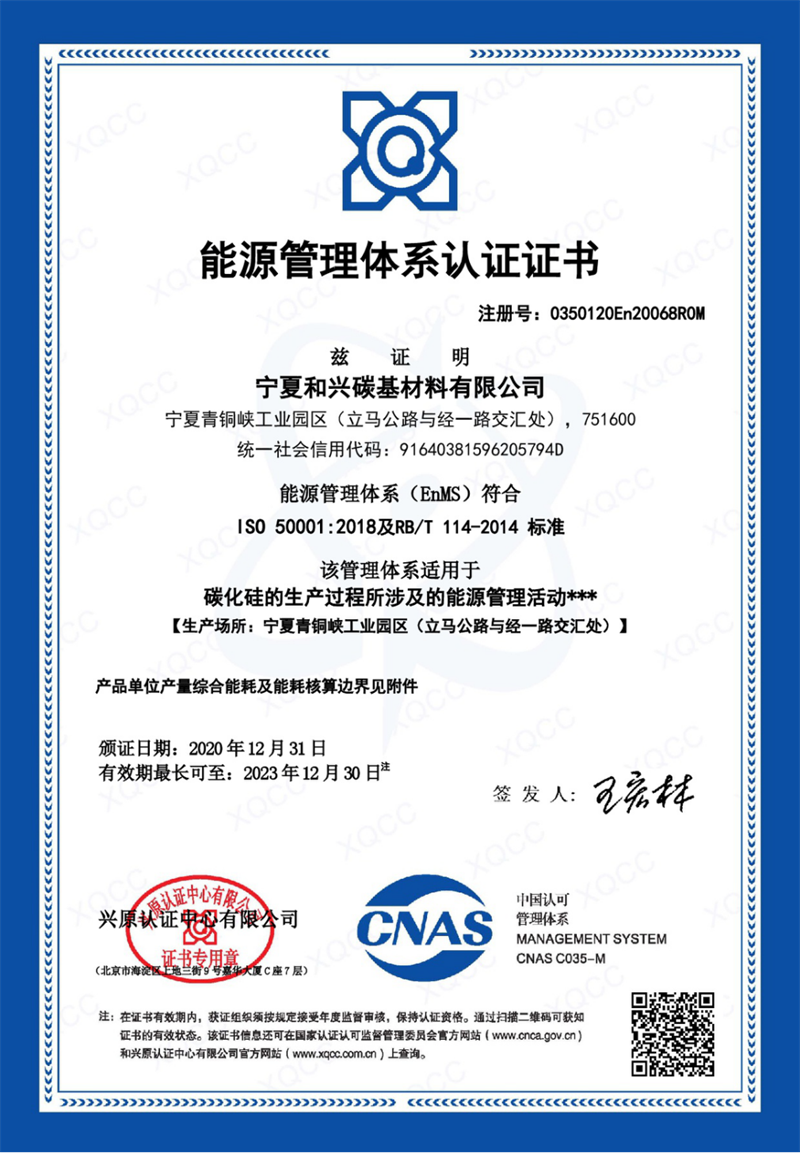

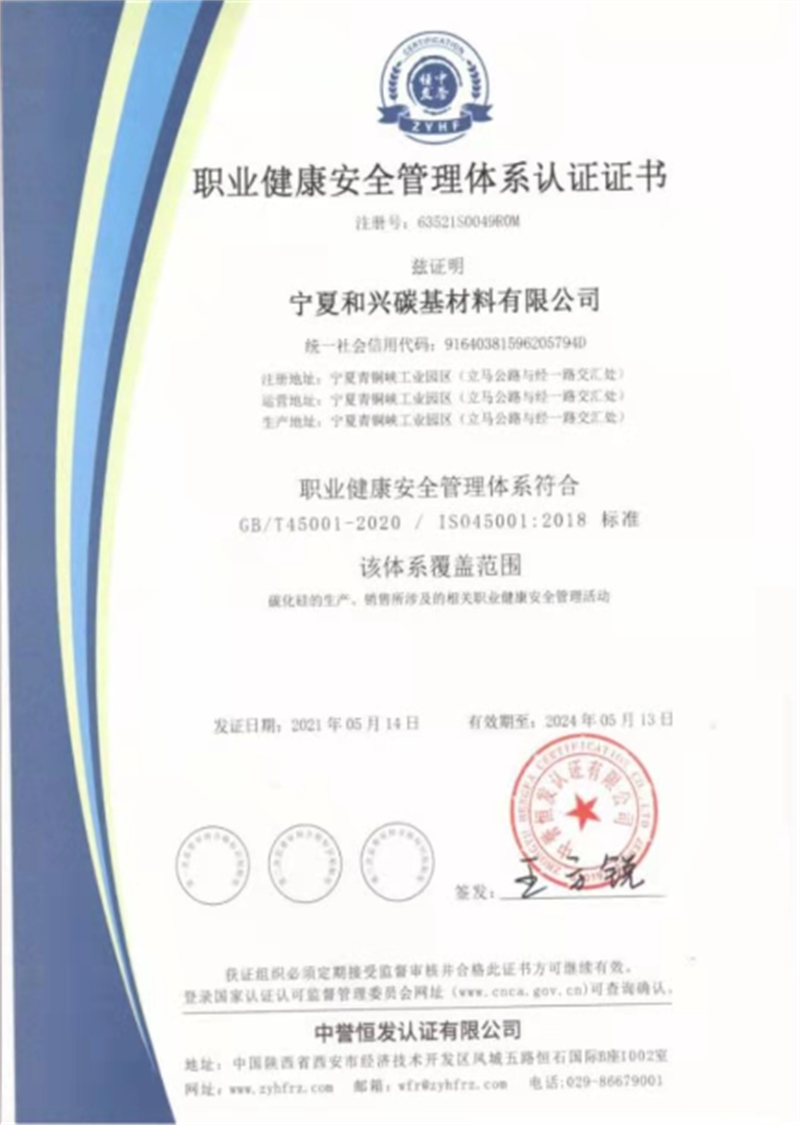

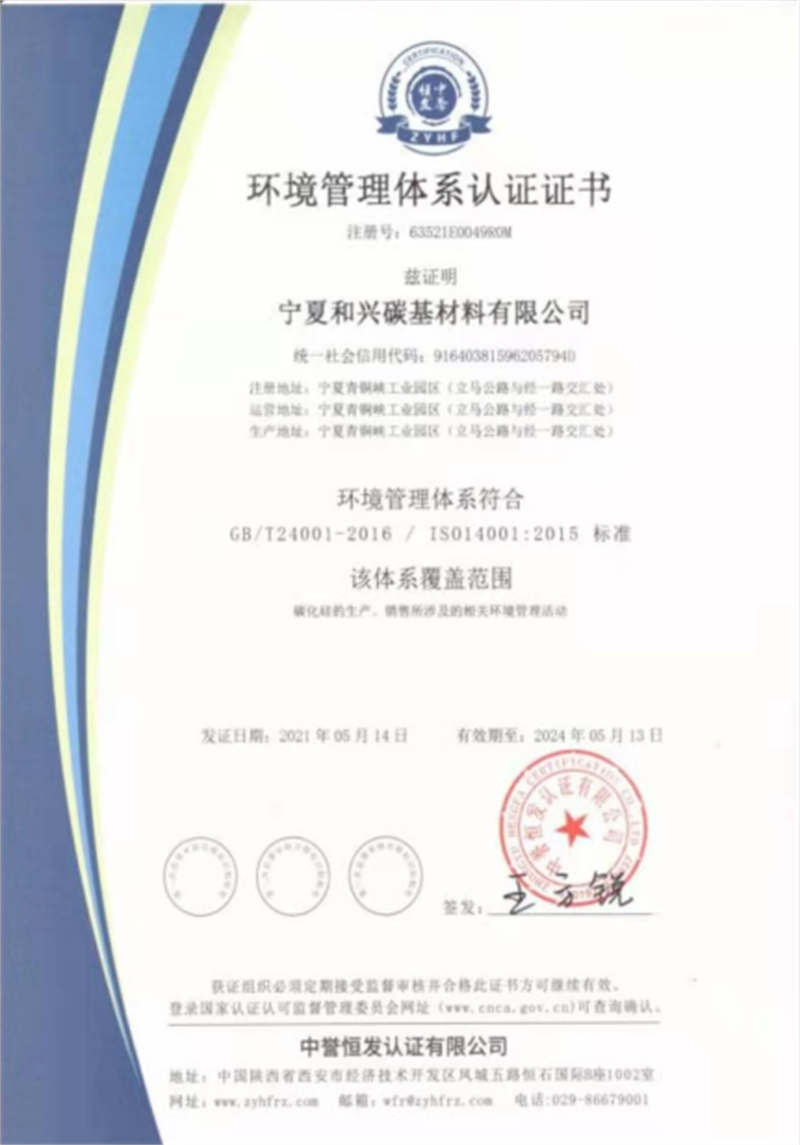

- Certification:

- Reach, ISO

Q: Do you have any in stock?

A: Our company has a long-term stock of spot, to meet customer requirements.

Q: Can we customize special products?

A: Our company has a professional team to customize and produce all kinds of products for customers.

Q: Can you solve the problems in the use of your products?

A: Yes. Our company has long accumulated experience, can solve all the problems in the use process.

Q: Do you have any experience in reducing tariffs or costs for exports?

A: Our company has professional team to reduce costs for customers.

Q: Does your company's production capacity meet the needs of customers?

A: Our company has strong strength, stable and long-term ability to meet various needs of customers.

Q: Can you make products according to customer's requirements?

A: We can meet all kinds of customized products required by customers.

Details Images

Packing&Delivery

Ningxia Hexing Carbon-based Materials Co., Ltd. was established in May 2012 with a registered capital of 40 million yuan. It is mainly engaged in the production and sales of refractory and wear-resistant carbon-based materials such as silicon carbide. It has an annual production capacity of 70,000 tons of silicon carbide. The silicon carbiNingxia Hexing Carbon-based Materials Co., Ltd. was established in May 2012 with a registered capital of 40 million yuan. It is mainly engaged in the production and sales of refractory and wear-resistant carbon-based materials such as silicon carbide. It has an annual production capacity of 70,000 tons of silicon carbide. The silicon carbide-like powder deep processing production line has been fully completed. The company's various products are sold well in the Mainland and exported to the Americas, Europe, Africa, Southeast Asia, Japan, South Korea and other countries. It has developed into a domestic silicon carbide industry leader and a benchmark in the Ningxia silicon carbide industry. Enterprise, Ningxia manufacturing demonstration leading enterprise, approved as a national high-tech enterprise in 2019 (the first in the silicon carbide smelting industry), approved as an autonomous region-level enterprise technology center in 2020, achieving sales revenue of 420 million yuan in 2019 and solving 200 jobs . In 2014, the company passed the ISO9001: 2008 quality system certification, and obtained the EU REACH certification, and has its own import and export rights. The laboratory is fully equipped, equipped with 7 particle size testing equipment, 3 muffle furnaces, 3 electronic analytical balances, 2 ovens and other supporting testing equipment. There are 9 laboratory personnel, all of whom have college degree or above, and have been trained and qualified by CIQ Ningxia Testing Center before taking up their jobs. The chemical analysis of the products is strictly implemented in accordance with the international standard "GB/T 3045-2003", and the raw materials and products are strictly checked for quality. Our company is mainly equipped with two silicon carbide productions with capacities of 32500KVA and 35000KVA, and the first supporting 110KVGIS power supply system in the country. The system has the characteristics of safety and reliability, low loss, high power conversion rate, and small footprint. The company is currently equipped with complete product deep processing equipment, which can process a variety of section sand, granular sand, fine powder, and micro powder products according to customer requirements. In 2016, after a year of production, experimentation and comparative analysis, we overcame the difficulties and solved the old problem that plagued the silicon carbide industry. Under the organization and leadership of the Silicon Carbide Association, silicon carbide companies from the whole region and neighboring provinces come to our company for visits, inspections, and learning. Our company's experience in solving the "bulging" phenomenon has been promoted and applied, which further enhances the company's influence in the industry. In 2016, the company introduced advanced technology to invest in a new silicon carbide fine processing production line that has been put into formal production. The goal of silicon carbide to be more "fine" processing has taken a new step. This model is the first among the national silicon carbide manufacturers, with an annual output value of 150 million. The company's products have been exported to the United States, Europe, Japan, South Korea, South Africa, Southeast Asia, Taiwan, China and other countries and regions. The company is carrying out all-round cooperation with customers in accordance with the corporate management philosophy of "unity, forge ahead, and pursuit of excellence". The reputation of the company's products in the domestic and foreign markets is getting higher and higher. For the domestic market, the company's products are mainly used in the engineering ceramic material industry, and have established good cooperative relations with well-known domestic enterprises such as Sinosteel Group, Pu Nai New Materials, Hanjiang Group, Wuhan Iron and Steel Refractory. For the international market, our choices for customers have shifted from exporting low-end metallurgical materials to casting materials and refractory materials, and from the traditional American market to the European market. The added value of our products has been greatly improved. We have become the main supplier of ThyssenKrupp of Germany, Norma of Germany, National Refractories of Sweden, and Selma of Belgium. Hexing keeps improving on equipment, and puts emphasis on safety, energy saving and environmental protection in management, and strives to build Hexing into an excellent benchmark enterprise that keeps pace with the timesde-like powder deep processing production line has been fully completed. The company's various products are sold well in the Mainland and exported to the Americas, Europe, Africa, Southeast Asia, Japan, South Korea and other countries. It has developed into a domestic silicon carbide industry leader and a benchmark in the Ningxia silicon carbide industry. Enterprise, Ningxia manufacturing demonstration leading enterprise, approved as a national high-tech enterprise in 2019 (the first in the silicon carbide smelting industry), approved as an autonomous region-level enterprise technology center in 2020, achieving sales revenue of 420 million yuan in 2019 and solving 200 jobs .

In 2014, the company passed the ISO9001: 2008 quality system certification, and obtained the EU REACH certification, and has its own import and export rights. The laboratory is fully equipped, equipped with 7 particle size testing equipment, 3 muffle furnaces, 3 electronic analytical balances, 2 ovens and other supporting testing equipment. There are 9 laboratory personnel, all of whom have college degree or above, and have been trained and qualified by CIQ Ningxia Testing Center before taking up their jobs. The chemical analysis of the products is strictly implemented in accordance with the international standard "GB/T 3045-2003", and the raw materials and products are strictly checked for quality.

Our company is mainly equipped with two silicon carbide productions with capacities of 32500KVA and 35000KVA, and the first supporting 110KVGIS power supply system in the country. The system has the characteristics of safety and reliability, low loss, high power conversion rate, and small footprint. The company is currently equipped with complete product deep processing equipment, which can process a variety of section sand, granular sand, fine powder, and micro powder products according to customer requirements.

In 2016, after a year of production, experimentation and comparative analysis, we overcame the difficulties and solved the old problem that plagued the silicon carbide industry. Under the organization and leadership of the Silicon Carbide Association, silicon carbide companies from the whole region and neighboring provinces come to our company for visits, inspections, and learning.

Our company's experience in solving the "bulging" phenomenon has been promoted and applied, which further enhances the company's influence in the industry.

In 2016, the company introduced advanced technology to invest in a new silicon carbide fine processing production line that has been put into formal production. The goal of silicon carbide to be more "fine" processing has taken a new step. This model is the first among the national silicon carbide manufacturers, with an annual output value of 150 million.

The company's products have been exported to the United States, Europe, Japan, South Korea, South Africa, Southeast Asia, Taiwan, China and other countries and regions. The company is carrying out all-round cooperation with customers in accordance with the corporate management philosophy of "unity, forge ahead, and pursuit of excellence". The reputation of the company's products in the domestic and foreign markets is getting higher and higher. For the domestic market, the company's products are mainly used in the engineering ceramic material industry, and have established good cooperative relations with well-known domestic enterprises such as Sinosteel Group, Pu Nai New Materials, Hanjiang Group, Wuhan Iron and Steel Refractory. For the international market, our choices for customers have shifted from exporting low-end metallurgical materials to casting materials and refractory materials, and from the traditional American market to the European market. The added value of our products has been greatly improved. We have become the main supplier of ThyssenKrupp of Germany, Norma of Germany, National Refractories of Sweden, and Selma of Belgium.

Hexing keeps improving on equipment, and puts emphasis on safety, energy saving and environmental protection in management, and strives to build Hexing into an excellent benchmark enterprise that keeps pace with the times.